Doctor Blade Coating Method

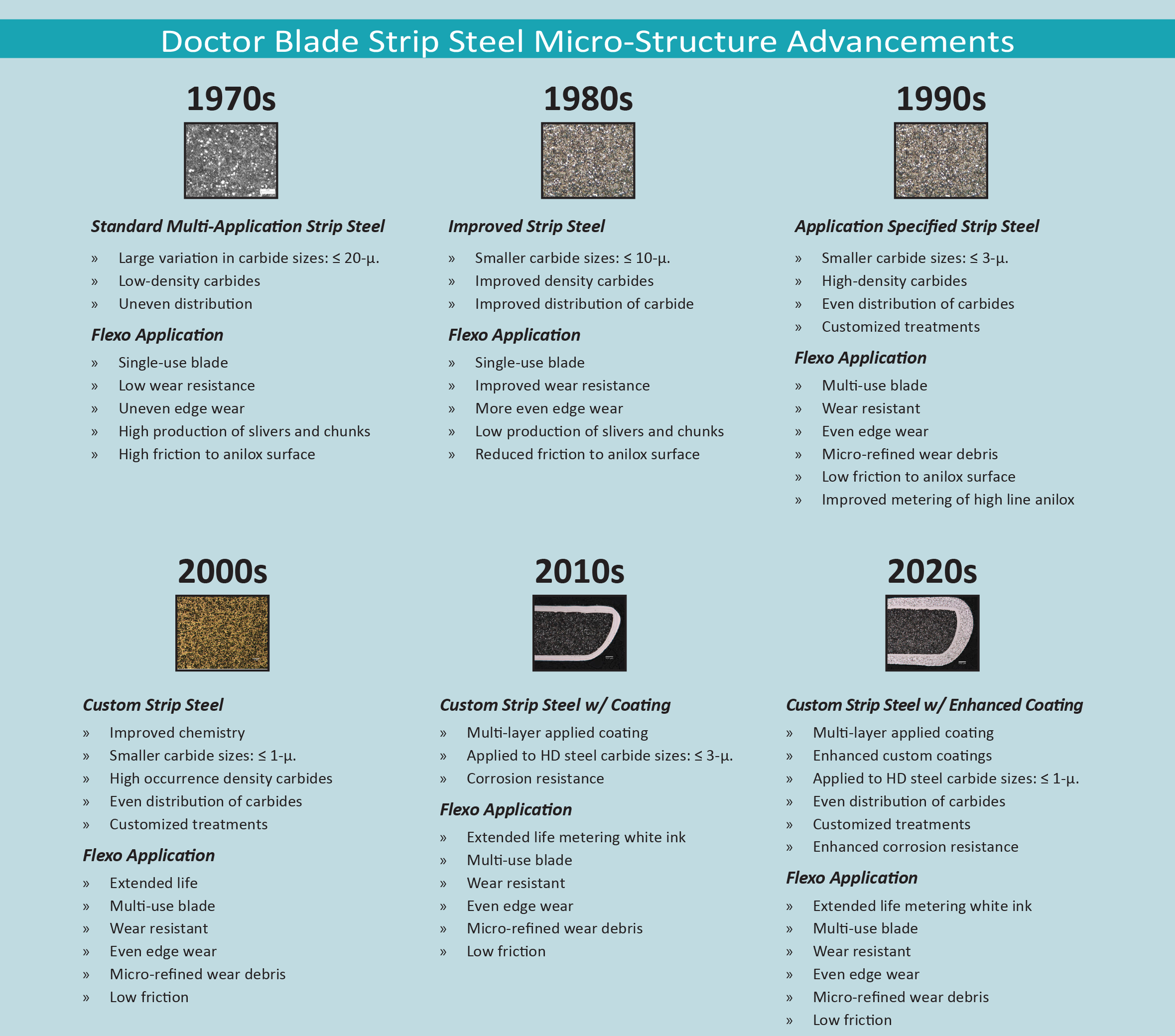

Refining Doctor Blade Technology Flxon

Valmet S Blade Coating Station

The Role Of Physical Techniques On The Preparation Of Photoanodes For Dye Sensitized Solar Cells

Microwave Processed Copper Zinc Tin Sulphide Czts Inks For Coatings In Solar Cells Springerlink

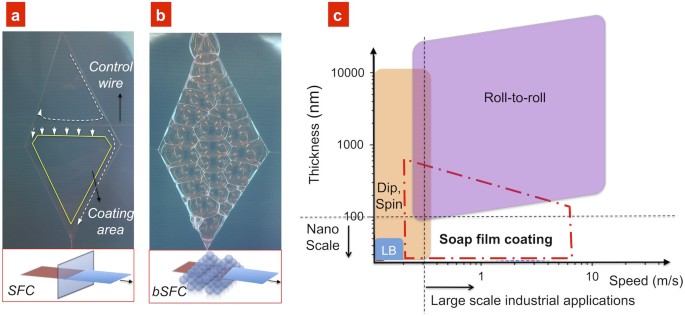

Soap Film Coating High Speed Deposition Of Multilayer Nanofilms Scientific Reports

Latest Review Of Coating Methods 2 Oct 16

Common problems caused by lower quality or incorrect type of doctor blades include scoring of the anilox roller and UV ink spitting Using a fitforpurpose doctor blade will prevent issues, and it does not pay off to save on your metering equipment By Neel Madsen Cutting corners is never advisable in flexo printing a process that relies heavily on getting each element right in order for.

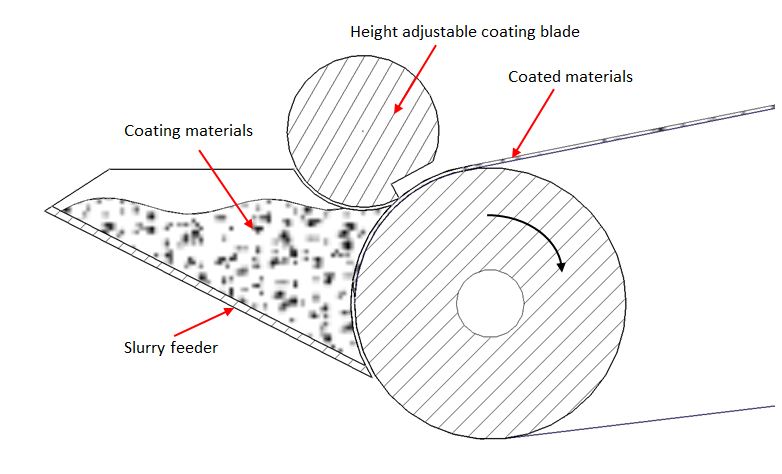

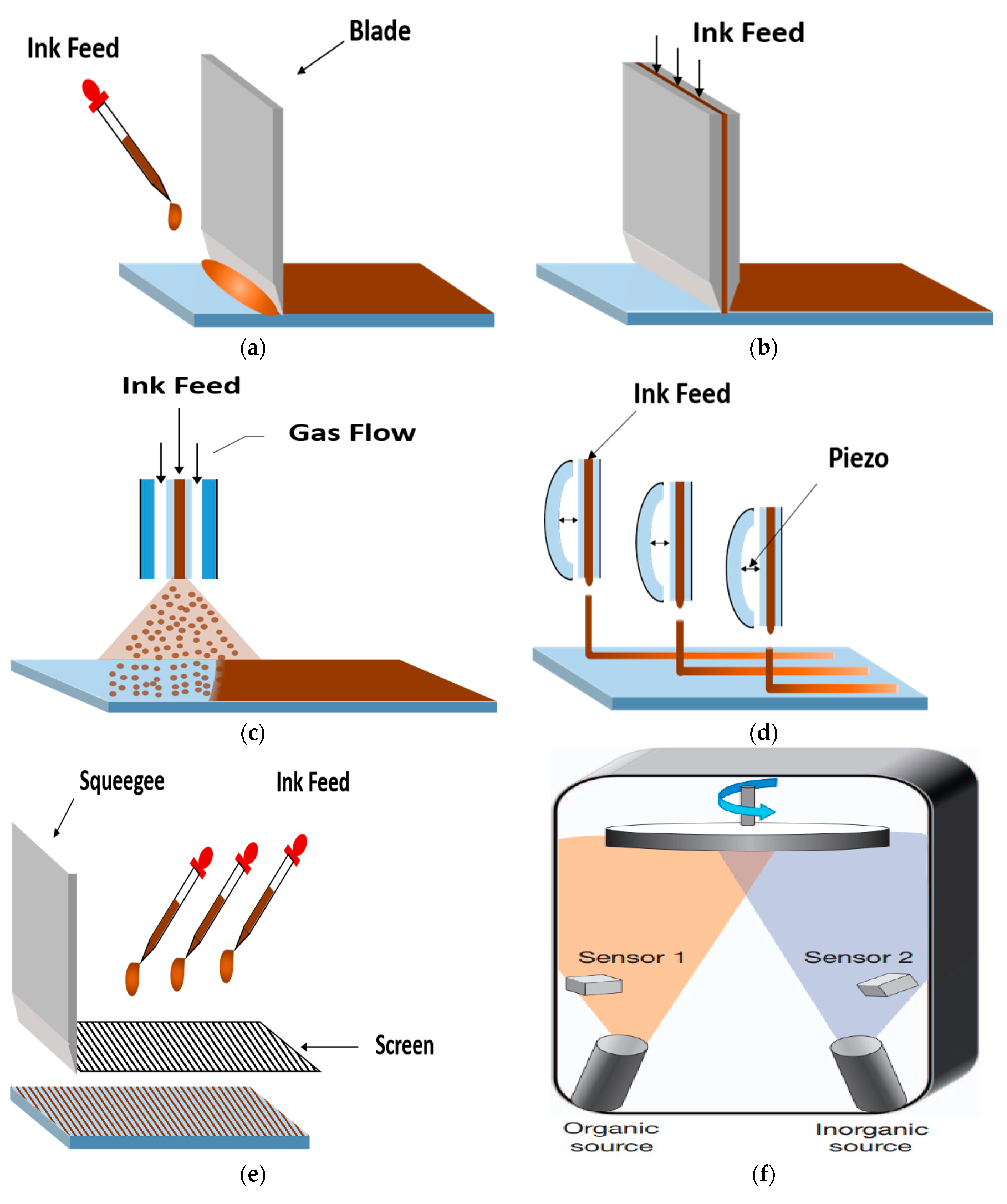

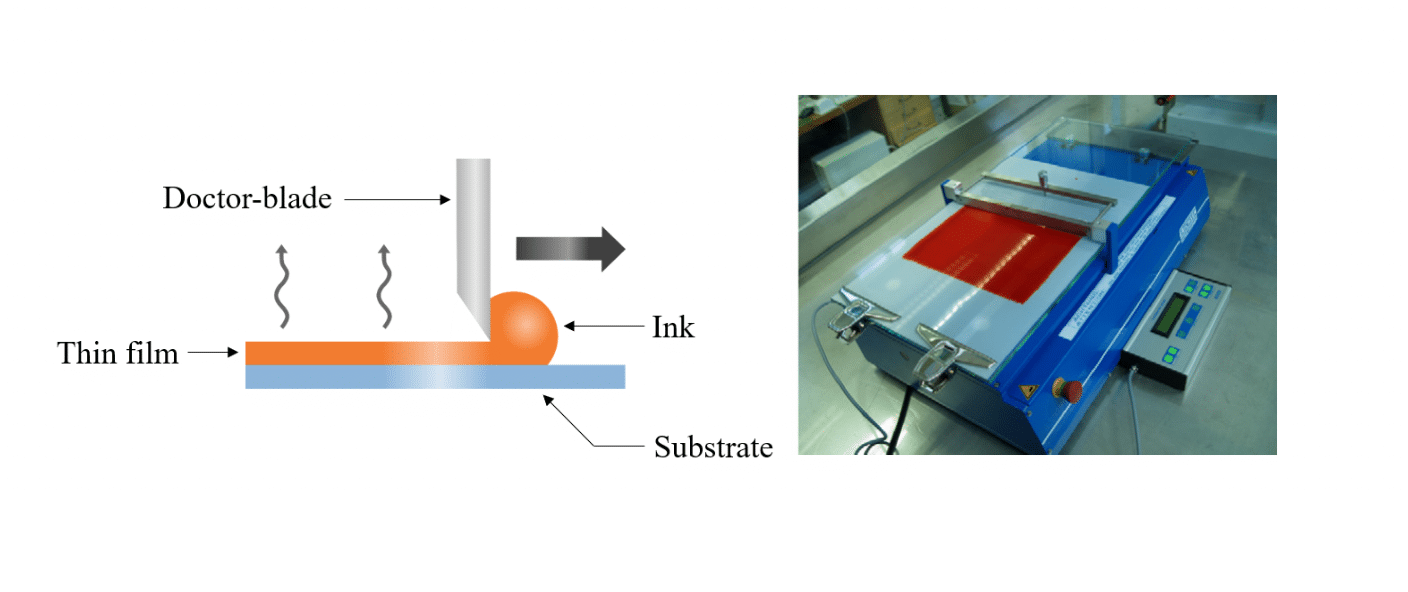

Doctor blade coating method. What is Dr Blade?. Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors and is now an accepted precision coat ing method. The present invention refers to a doctor blade ( 1 ) comprising a metal support ( 3 ) completely coated with a polymeric material The doctor blade ( 1 ) works in combination with a cylinder ( 2 ) and consists of a steel support ( 3 ) with a polished surface coated with a layer of variable thickness of polymeric material, comprising an ultrathin layer ( 0 ) which coats the whole surface of.

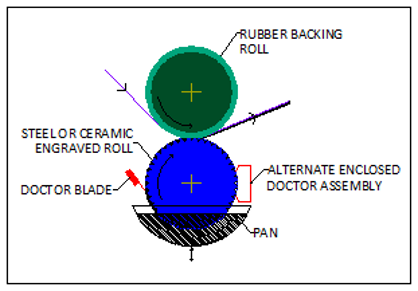

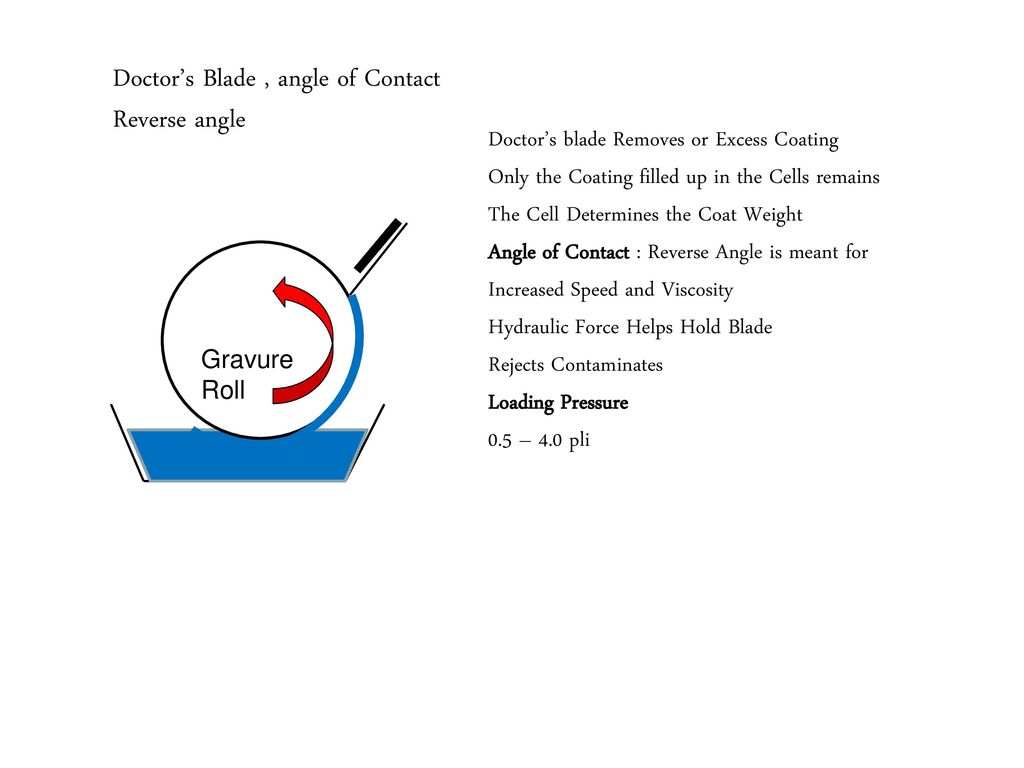

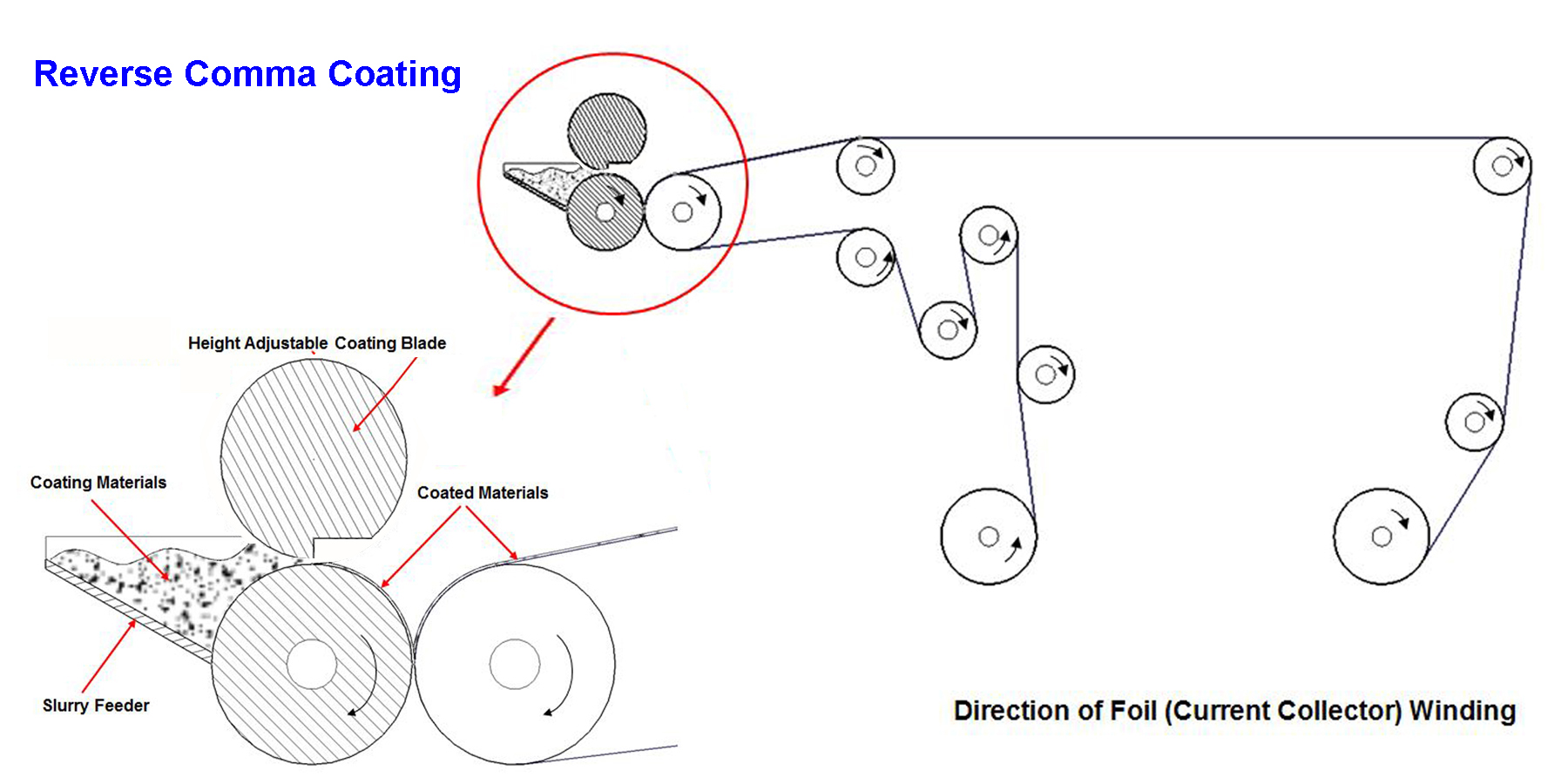

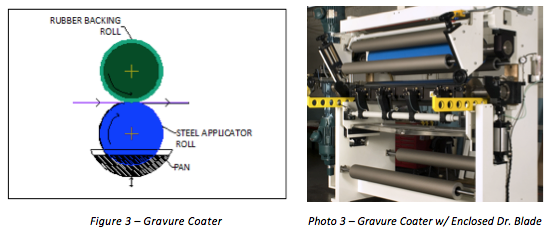

Doctor Blades are extremely smooth lamella and non lamella ( round edge) blades and used for wiping out the excess ink in flexographic or rotogravure printing and coating processes They are also used for printing and coating on paper, films sch as PET, BOPP, PVC and foils used in packaging labeling, publication & corrugation industries. Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors 1 and is now an accepted precision coating method. Offset Gravure coating is a coating method consisting of 3 roller and typically an enclosed doctor blade The first roller is a gravure roller with a defined gravure shape and depth On this roller the doctor blade is mounted to apply solvent based, water based or 100% solid coating materials.

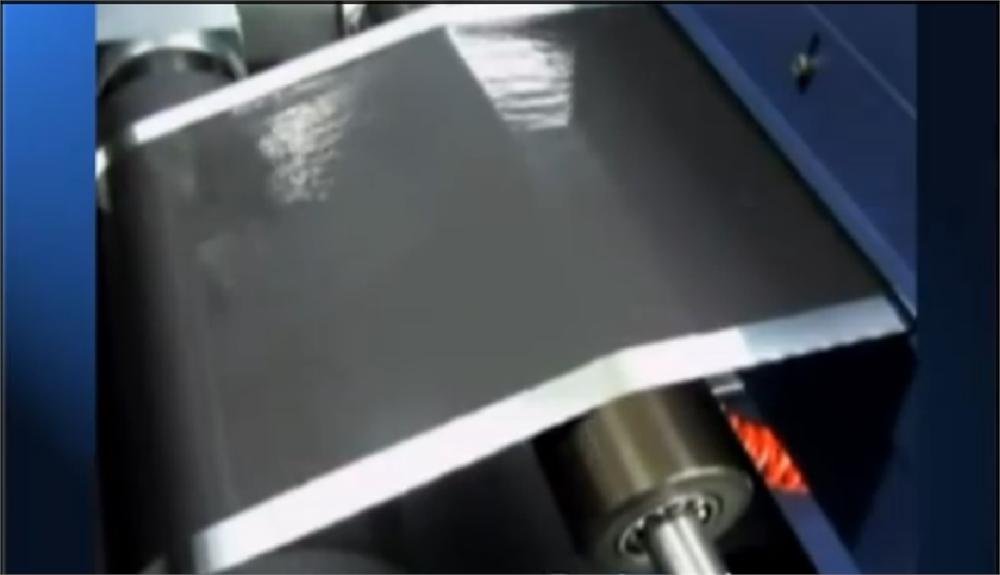

Doctor blade assembly to remove the excess coating In this method all the rolls are turning in the same direction at the point of contact at each nip The backup roll is operating at line speed, the applicator roll most usually is operating at 98% of line speed (∓5%), and the gravure roll. After the coating fluid on the surface of the gravure roll is wiped off with the doctor blade, the fluid remaining in the pits are transferred onto the web of the target (substrate) Changing the coating thickness requires changing the gravure roll to one engraved with a different pattern. This method, aptly named tape casting, knife coating, or knifeoveredge coating, due to transfer to reelto reel coating (R2R), is also viable to be used to make films for polymer solar cells The stages of this technique are summarized as the movement of a substrate at a constant speed under a blade, with a specific height and contact angle.

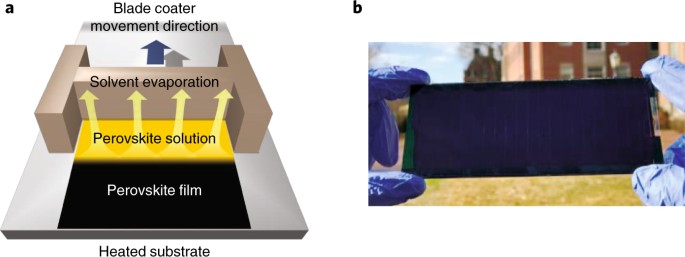

An object of the present invention is to prevent a doctor blade from being scraped by a filler contained in a coating liquid The surface of the doctor blade (1) for scraping off the coating liquid on the peripheral surface (6) of the coating roller (5) for applying a coating liquid containing a filler to a traveling separator is made of ultrahigh molecular weight polyethylene. The development of the technologies for scalable deposition of perovskite layer started from the utilization of the doctor blade technique, as an alternative to spin coating. 1,602 doctor blade coating products are offered for sale by suppliers on Alibabacom A wide variety of doctor blade coating options are available to you, There are 801 suppliers who sells doctor blade coating on Alibabacom, mainly located in Asia The top countries of suppliers are China, Pakistan, from which the percentage of doctor blade.

The coating reduces friction and increases the blade lifetime SWED/CUT® Doctor Blades comprehensive product range covers all types of blades, from those made of plastic or composite materials to blades made of extremely high alloyed and corrosion free steel which is then ground, in some cases surface coated and refined for various applications. Doctor blading also known as knife coating or blade coating is a popular thinfilm fabrication technique It involves either running a blade over the substrate or moving a substrate underneath the blade There is a small gap that determines how much solution can get through Here, solution is effectively spread over the substrate. Doctor blade coating is an efficient method for realizing high precision catalyst loading with high reproducibility while also being faster than hand painting Pt/C(DBC) with and without SiO 2 catalysts had CLs of 02 mg Pt cm −2.

Runnability is also improved because of a smaller doctor blade load compared to other application methods Jet application also has excellent efficiency even at very high speeds Uniform coating quality OptiCoat Jet produces high quality coating on paper and board in both cross and machine direction. We have successfully transferred the solution processing of perovskite ink from spin coating to the scalable blade coating method We have studied the proces. Doctorblade coating (DBC) is a rolltoroll compatible highthroughput thin film fabrication route with little solution wastage and is considered as a more scalable method for the fabrication of organic solar cells (OSCs) than spin coating (SC) Since wet film drying is much slower during DBC than during SC.

An object of the present invention is to prevent a doctor blade from being scraped by a filler contained in a coating liquid The surface of the doctor blade (1) for scraping off the coating liquid. Offset Gravure coating is a coating method consisting of 3 roller and typically an enclosed doctor blade The first roller is a gravure roller with a defined gravure shape and depth On this roller the doctor blade is mounted to apply solvent based, water based or 100% solid coating materials. PrimeBlade Sweden AB is a global manufacturer and supplier of Doctor Blades for flexo, gravure, offset printers, and coating applications Together with our Swedish raw material supplier and end users the doctor blade was produced to improve production quality, blade life, and to increase machine speeds.

The excess coating on the roller is wiped off by the Doctor Blade and the coating is then deposited onto the substrate as it passes between the Engraved roller and a Pressure Roller There are three different ways of gravure roll manufacturing The trailing blade coating method scrapes away excessive coating, but leaves a thickandthin. Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. There are many coating process available, direct or reverse gravure, reverse roll, die coaters, wire bars, blade or doctor blade coaters, kiss gravure method 1) Standard gravure coating method in this process a cylindrical gravure roll with diameters 125 to 250 mm used, which revolves in the adhesive pan in reverse direction.

Even though the doctorblade coating technique has been widely used to prepare PSCs, it is yet to be applied to highefficiency PSCs under ambient conditions (RH∼45%, RT∼25 °C) In this study, we conducted bladecoating fabrication of modified highefficiency PSCs under such conditions. Photographs of the hierarchical nanoporous membranes created using a doctor blade coating method A, Photograph of largearea HNM (10 × 10 cm2 ) fabricated by a doctorblade method. Our services Materials development and optimization for customer coating processes;.

In printing the doctor blade removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and "ductor" became doctor. Common problems caused by lower quality or incorrect type of doctor blades include scoring of the anilox roller and UV ink spitting Using a fitforpurpose doctor blade will prevent issues, and it does not pay off to save on your metering equipment By Neel Madsen Cutting corners is never advisable in flexo printing a process that relies heavily on getting each element right in order for. Coating fluid is pooled between the applicator roll and the substrate, and the blade on the roll wipes off excessive fluid to ensure an optimum coating thickness This method is generally suited for highly viscous coating fluids or when forming a thick coating However, some models can support various coating thicknesses Examples of other methods.

The coating is applied to the applicator roll either from a pan in which the roll is immersed or from an enclosed applicator feed system In most instances, excess coating is removed from the land surfaces by a flexible doctor blade pressing against the rotating roll The choice of the feed system is often speed and process related. The nip giving a smooth coating Doctor Blade Applicator roll The three roll reverse coater is used for many specially applications This method is more expensive and generally slower in line speed than the Mayer rod coater However, the versatility in terms of coat weight range and coating width, and the good coat quality of the three roll. It is used in a reverse kiss coating method in which the roll is partially submerged in a pan of solution The roll rotates in the opposite direction of the web, and the cells pick up the coating solution The flexible doctor blade lightly smoothes off the excess and the precisely measured solution in the cells is then transferred to the web.

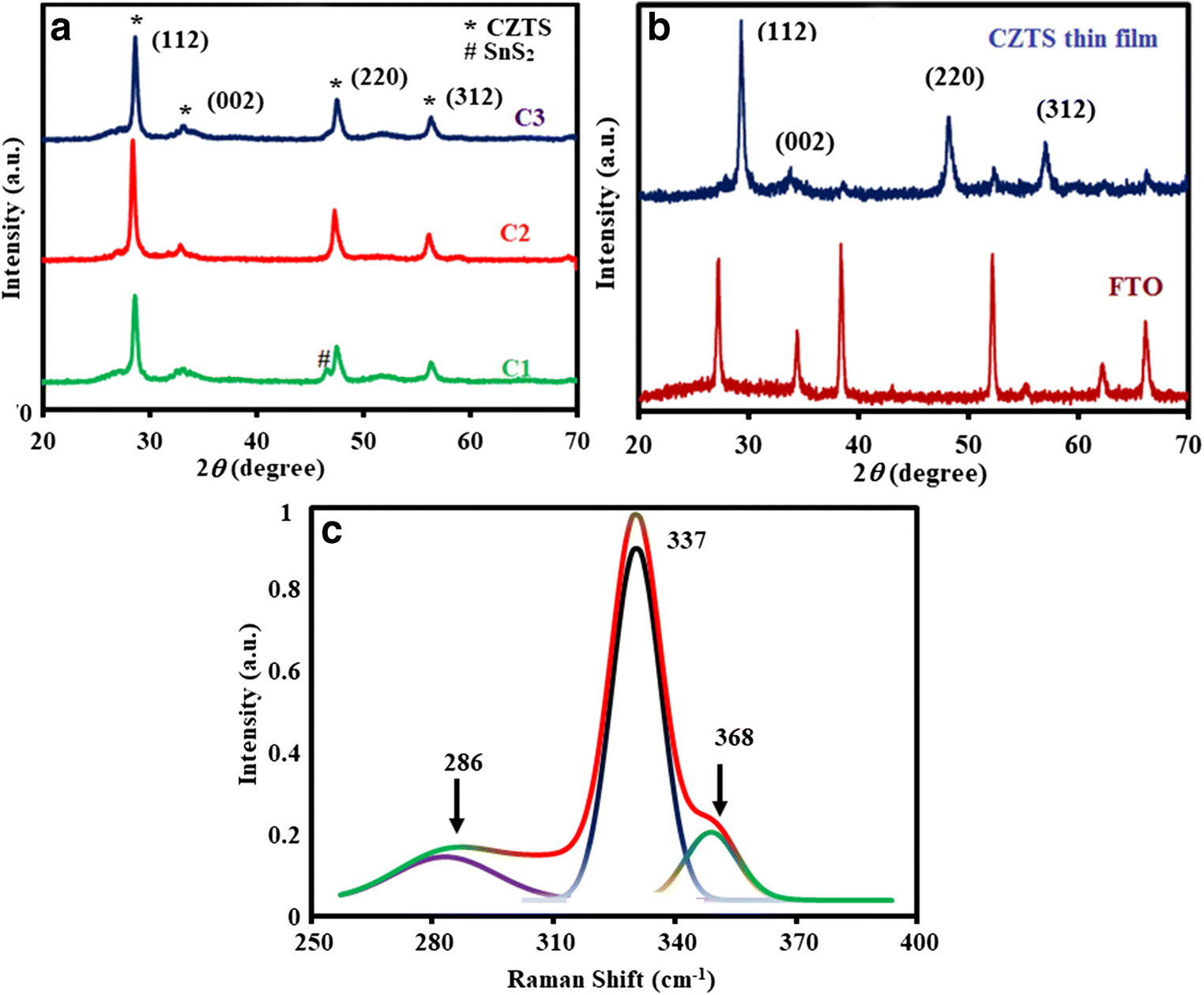

Photographs of the hierarchical nanoporous membranes created using a doctor blade coating method A, Photograph of largearea HNM (10 × 10 cm2 ) fabricated by a doctorblade method. In order to improve photovoltaic performance of to make a thin film using a doctorblade method 11 DSSC, spray coating 3, 4, screen printing 57 and The obtained Ti02 thin film was then dried in air for 30 liquid phase crystal deposition (LPCD) 8 methods have min. In printing the doctor blade (from ductor blade) removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used.

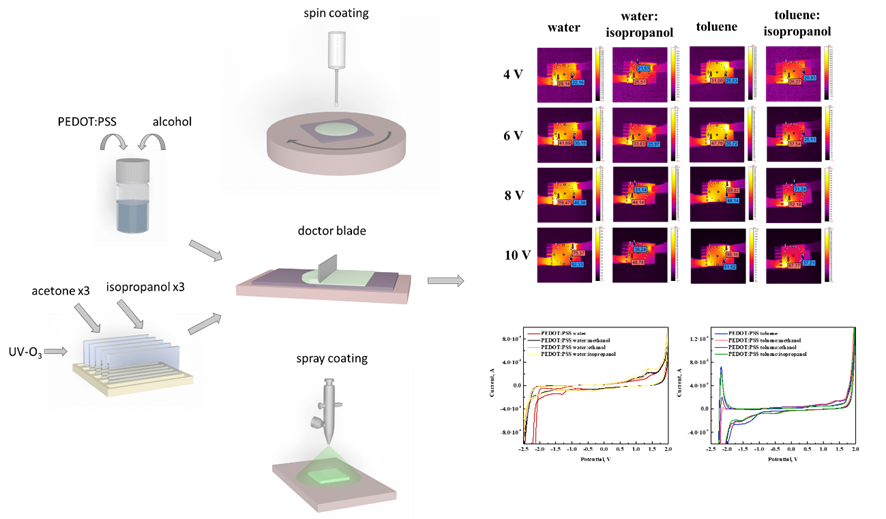

Doctor blade manufacturers have found a way to make new polymer doctor blade materials that can overcome the limitations of steel in specialty coating applications By engineering a modified lamella tip, known as a “MicroTip”, on these materials, they have introduced a doctor blade product that offers the best of traditional plastic and steel. The current work reports the fabrication of fully coated inverted organic solar cells by combining doctorblade coating and spray coating and, more importantly, demonstrates that a nanocomposite of a polyoxometalate and conjugated polymer could be an excellent anode buffer layer for the fully coated polymer solar cells with favorable. The present invention refers to a doctor blade comprising a metal support completely coated with a polymeric material, in particular Teflon s®, and a method of coating said support Doctor blades are wellknown tools and are normally used to remove from a cylindrical surface—with a finite radius (cylinder) or an infinite radius (flat surface.

Interestingly, the carrier diffusion length in doctorbladed OTP films is beyond 35 μm which is significantly larger than in the spincoated films, due to the formation of crystalline grains with a very large size by the doctorblade coating method. Some methods have already existed, for example, doctor blade, electrophoresis, spin coating, and so forth, in the laboratory, which are not convenient for rapid and mass production A standard procedure for fabrication of the photoelec e new method removed the. The excess coating on the roller is wiped off by the Doctor Blade and the coating is then deposited onto the substrate as it passes between the Engraved roller and a Pressure Roller There are three different ways of gravure roll manufacturing The trailing blade coating method scrapes away excessive coating, but leaves a thickandthin.

The present invention refers to a doctor blade comprising a metal support completely coated with a polymeric material, in particular Teflon s®, and a method of coating said support Doctor blades are wellknown tools and are normally used to remove from a cylindrical surface—with a finite radius (cylinder) or an infinite radius (flat surface. Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. Doctor blade coated with polymeric material and coating method Patent number Abstract The present invention refers to a doctor blade (1) comprising a metal support (3) completely coated with a polymeric material.

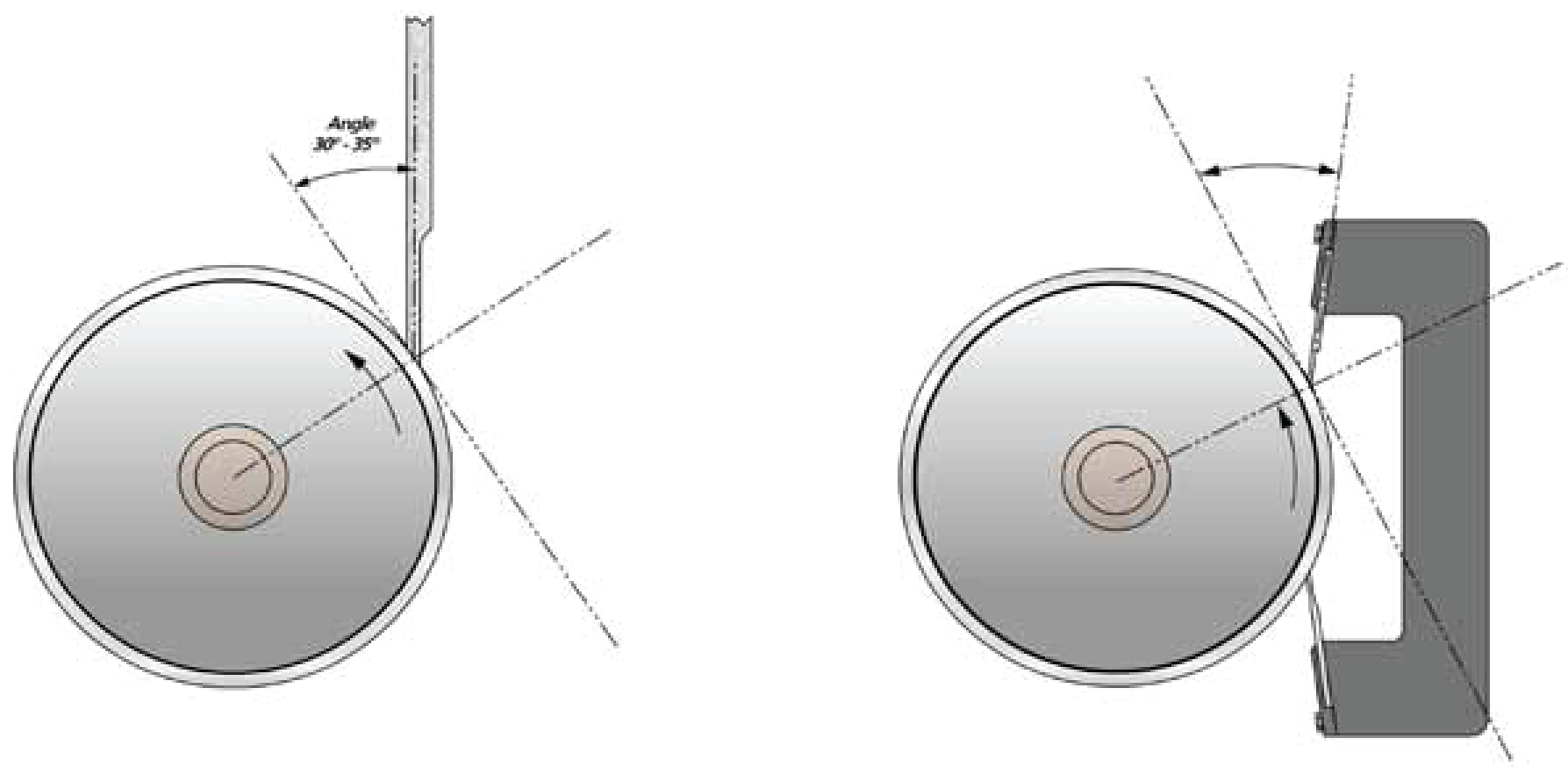

Rolltoroll coating under clean room conditions (ISO 100 000) Dip coating (up to a size of 1 m) Milling (flexible and solid substrates) Spinning;. The angle at which the blade comes into contact with the anilox roll is also crucial to proper doctor blade installation and optimum blade performance Ideally, the contact angle should be 30° tangent to the anilox roll circumference In reverse angle and chamber blade applications, the doctor blade angle should be between 28° and 32°. Tion of HTLfree devices by the bladecoating method faces more challenges due to rougher and more nonuniform perovskite films, than do those prepared by spincoating with the antisolvent method Here we report a moleculardoping strategy for a perovskite layer to doctorblade HTLfree PSCs with a simplified device.

Gravure coating is a proven tinting and coating transfer method utilizing one rubber covered roll and one steel or ceramic covered roll Coatings are applied and metered to the engraved roll via a pan and single blade system or an enclosed doctor blade system As the engraved roll rotates, the fluid is delivered to the engraved cells, metered and then transferred to the substrate at the nip. Some methods have already existed, for example, doctor blade, electrophoresis, spin coating, and so forth, in the laboratory, which are not convenient for rapid and mass production A standard procedure for fabrication of the photoelec e new method removed the. Smooth paper surfaces are achieved with the blade coating method, whereby an excess of coating medium is initially applied onto the paper and is then doctored off with a doctor blade Due to the pressure exerted on the coating medium by the doctor blade which is referred to as a coating blade the indentations on the paper surface are filled.

For more information, visit our websitehttp//inbguacil/teva/chem/eng/mennysh/Pages/defaultaspxMusic CreditsIt's Near by Dj QuadsDj Quads on Soundcloud. Piezoelectric materials and capacitors and is now an accepted precision coating method Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and. A set of opaque films were prepared with Degussa P25 ® or Hombikat UV100 ® TiO 2 powders by the doctor blade method on glass slides with different compositions of polyethylene glycol of kDa (PEG), and they were characterized by spectroscopy, microscopy and photochemical kinetics measurements After annealing treatment at 450 °C, about 5–7% C atom was incorporated into the films, as a.

Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. We have successfully transferred the solution processing of perovskite ink from spin coating to the scalable blade coating method We have studied the proces. Doctor Blades are actually an essential part of commercial printing While there are many methods of printing, there are two predominant methods that use Doctor Blades They are called Rotogravure (gravure), and Flexographic (flexo) printing In both Gravure and Flexo printing, the doctor blade is technically a metering blade.

Unlike direct gravure, where it is important to wipe the surface of the gravure roll clean, light doctor blade pressure is often used in this method so that coating stays on the surface of the gravure roll (as well as in the cells). Doctor Blades are actually an essential part of commercial printing While there are many methods of printing, there are two predominant methods that use Doctor Blades They are called Rotogravure (gravure), and Flexographic (flexo) printing In both Gravure and Flexo printing, the doctor blade is technically a metering blade. Screen and pad printing ;.

Blade coating method Broader context Doctorblade coating is a scalable, simple, lowcost, low temperature, solution based thin film deposition technique that is compatible with rolltoroll fabrication of large area devices with a high throughput Here we show that the large area (1 in 1 in) organolead trihalide perovskite (OTP) solar cells. Unlike direct gravure, where it is important to wipe the surface of the gravure roll clean, light doctor blade pressure is often used in this method so that coating stays on the surface of the gravure roll (as well as in the cells). Swedish steel has exceptionally high quality We can completely rely on its strength, which makes it possible for us to deliver precision made, highclass products under the SWED/CUT® brand year after year Swedev has developed a patented surface coating method in cooperation with highly demanding printers The coating reduces frictionRead More.

Coating and Varnishing Proact doctor blade chambers produce constant print quality and repeatability, They are manufactured from high strength woven carbon fibre The high strength woven carbon fibre minimises deflection and twisting in the chamber producing more consistent doctoring. Doctor blade assembly to remove the excess coating In this method all the rolls are turning in the same direction at the point of contact at each nip The backup roll is operating at line speed, the applicator roll most usually is operating at 98% of line speed (∓5%), and the gravure roll. 06presentation on coating methods 1 Coating Methods 2 Coating is a very Important process involved in Manufacture of Coated Products Today we shall review some of these as listed below The excess coating on the roller is wiped off by the Doctor Blade and the coating is then deposited onto the substrate as it passes between the Engraved.

Spin And Doctor Blade Coated Pedot Pss Back Electrodes In Inverted Organic Solar Cells Sciencedirect

Gravure Printing Process

Doctor Blade Method For Coating 10 Download Scientific Diagram

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

A Schematic Of The Doctor Blade Setup Reprinted With Permission From Download Scientific Diagram

Polymers Free Full Text Pedot Pss In Water And Toluene For Organic Devices Technical Approach

Figure 10 Czts Counter Electrode In Dye Sensitized Solar Cell Enhancement In Photo Conversion Efficiency With Morphology Of Tio 2 Nanostructured Thin Films Springerlink

Q Tbn And9gcsshisbs7kbj9djg54qxqrnbqyxd9j9dnz2emisgxtmfxr4inxw Usqp Cau

Knife Coating An Overview Sciencedirect Topics

Thin Film Coating Solution Processing Techniques Compared Ossila

Link Springer Com Content Pdf 10 1007 2f978 0 387 853 5 10 Pdf

Gravure Coating Equipment New Era Converting

Doctor Blading Materials Processing Britannica

Q Tbn And9gcrqfom5eh Obeko84ilmknr8a1hdcdtlimjignpu0llybdjuw5y Usqp Cau

Doctor Blade Coating And Screen Printing For Copper Based Soft Download Scientific Diagram

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

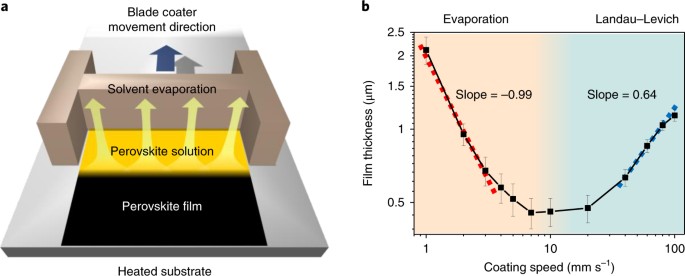

Tailoring Solvent Coordination For High Speed Room Temperature Blading Of Perovskite Photovoltaic Films Science Advances

Doctor Blade Pt Victory Blessings Indonesia

Doctor Blade Archives Flexoglobal Blog

A Generalized Crystallization Protocol For Scalable Deposition Of High Quality Perovskite Thin Films For Photovoltaic Applications Guo 19 Advanced Science Wiley Online Library

Fabrication Schema Of The Doctor Blade Method Download Scientific Diagram

Blade Coating Of Hybrid Perovskite Solar Cells Acs Energy Letters Youtube

Scheme Of Layer Preparation Using Doctor Blade Technique A Images Of Download Scientific Diagram

Doctor Blade Seals Advanced Supplies

Knife Coating An Overview Sciencedirect Topics

Photovoltaic Performance Of A N719 Dye Based Dye Sensitized Solar Cell With Transparent Macroporous Anti Ultraviolet Photonic Crystal Coatings Rsc Advances Rsc Publishing

Thin Film Coating Solution Processing Techniques Compared Ossila

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Morphology Control Strategies For Solution Processed Organic Semiconductor Thin Films Energy Environmental Science Rsc Publishing Doi 10 1039 C4ee006g

Doctor Blade For Rotogravure Printing Coating Machine Doctor Blade For Rotogravure Printing Manufacturer From Noida

Organic Solar Cells All Made By Blade And Slot Die Coating Techniques Sciencedirect

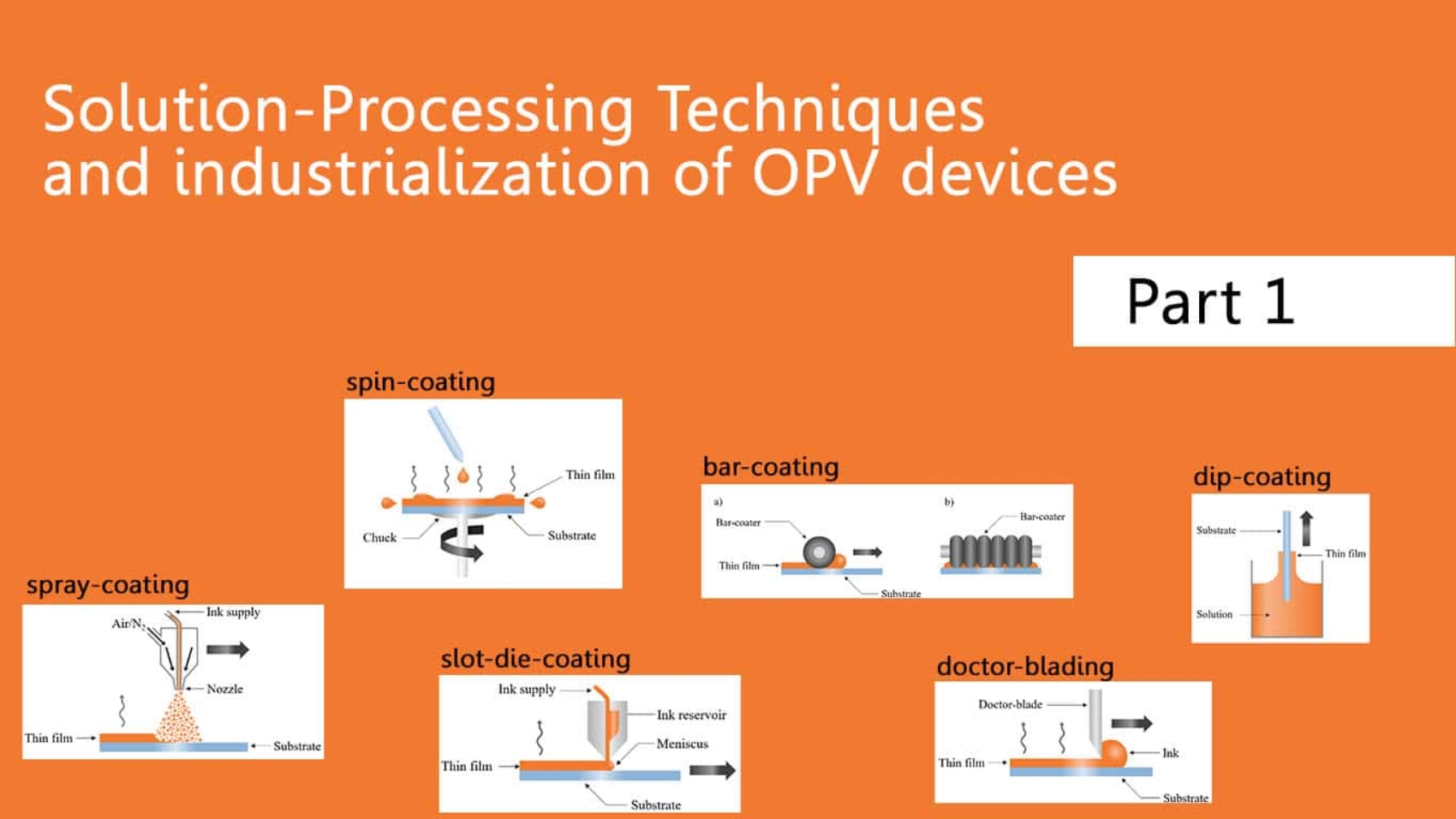

Thin Film Processing Method Part 1

Technical Coatings International Capabilities

A Review On Coating Methods For Adhesives By Shrikant Athavale Ppt Download

Thin Film Coating Solution Processing Techniques Compared Ossila

Hd Flexo Doctor Blades High Demand High Definition Flxon

China Doctor Blade For Paper Coating Machine China Coating Machine Scraper Scraper

Tsapps Nist Gov Publication Get Pdf Cfm Pub Id

Pubs Acs Org Doi Pdf 10 1021 Lav

Microgravure What Is Microgravure What Can Microgravure Do

Pdfs Semanticscholar Org 96c5 71db705b95fee6959 Pdf

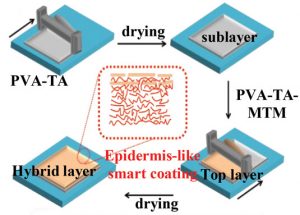

Creating A Scalable Strategy For Self Healing Skins Advanced Science News

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

Technical Coatings International Capabilities

Pdf Fabrication Of Dye Sensitized Solar Cell Using Spray Coating Method Agus Purwanto Academia Edu

Formation Of Blade And Slot Die Coated Small Molecule Multilayers For Oled Applications Studied Theoretically And By Xps Depth Profiling Aip Advances Vol 6 No 6

Towards Industrialization Of Polymer Solar Cells Material Processing For Upscaling Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C4tad

Interfacial Modification Of Hole Transport Layers For Efficient Large Area Perovskite Solar Cells Achieved Via Blade Coating Sciencedirect

Doctor Blade Coated With Polymeric Material And Coating Method Patent

12 Diagrams Of The A Spin Coating And B Doctor Blade Coating Download Scientific Diagram

Lab Facilities Multifunctional Materials Composites Mmc Laboratory

Thin Film Coating Solution Processing Techniques Compared Ossila

Pair Of Electrodes With The Method A Bar Coating B Doctor Blade Download Scientific Diagram

Q Tbn And9gcthtaggivapkkuuq6fowubddh 2klr0j0k7gjwjsojwzfa6mevp Usqp Cau

Our Three Commitments Product Information Fuji Shoko Co Ltd

Www Diva Portal Org Smash Get Diva2 Fulltext01 Pdf

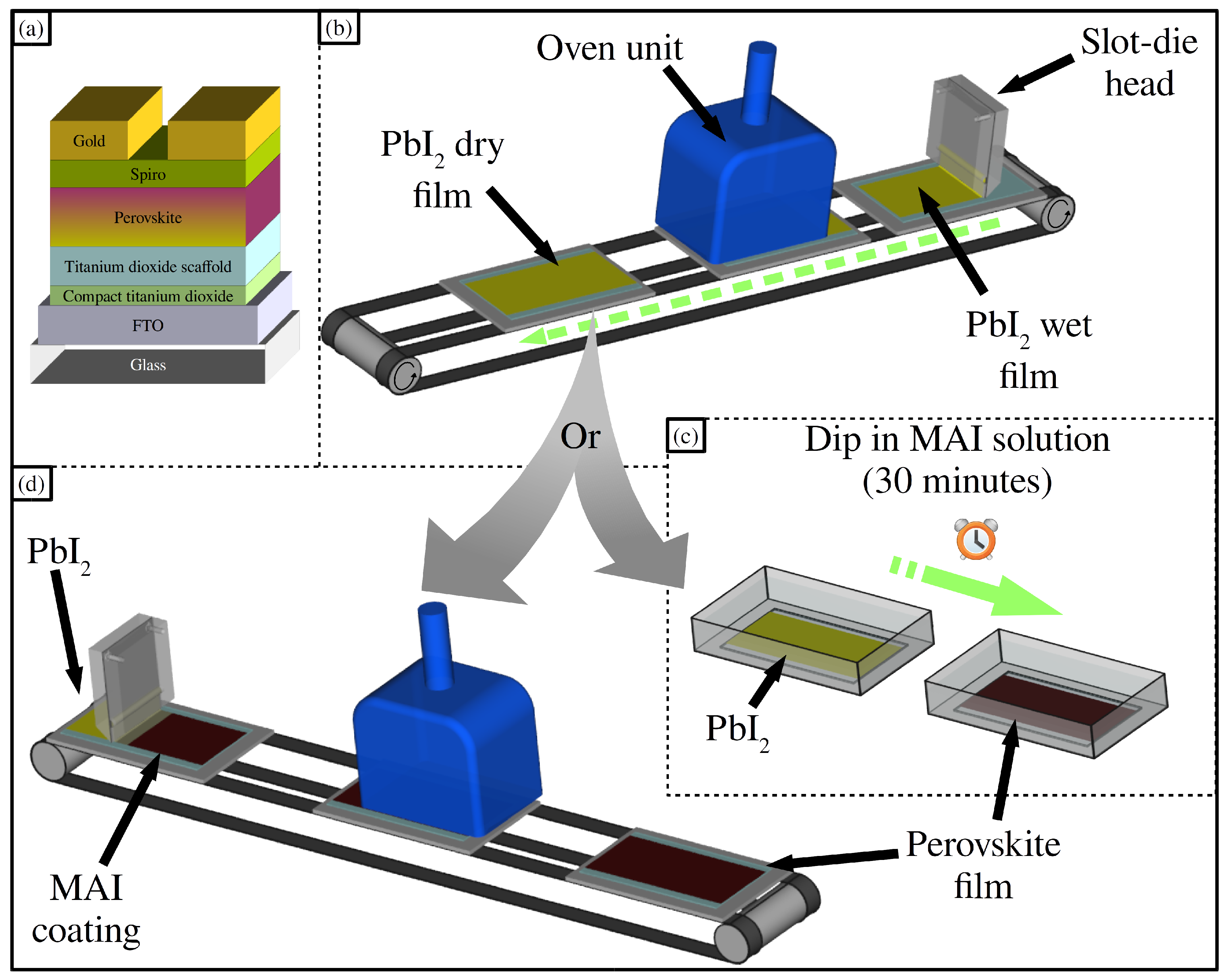

Materials Free Full Text Sequential Slot Die Deposition Of Perovskite Solar Cells Using Dimethylsulfoxide Lead Iodide Ink Html

Q Tbn And9gctne9atfp4kzaqi1z8nwc7oisrz6k3jaruqfysr3amddttqigod Usqp Cau

Surfactant Controlled Ink Drying Enables High Speed Deposition Of Perovskite Films For Efficient Photovoltaic Modules Nature Energy

Metals Free Full Text Major Impediment To Highly Efficient Stable And Low Cost Perovskite Solar Cells Html

Lab Compact Polymer Coating Coater With Doctor Blade Suppliers Price Lab Compact Polymer Coating Coater With Doctor Blade For Sale

Schematic Representation Doctor Blade Technique And Photograph Of Download Scientific Diagram

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing

Air Stable Efficient Mixed Cation Perovskite Solar Cells With Cu Electrode By Scalable Fabrication Of Active Layer Deng 16 Advanced Energy Materials Wiley Online Library

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Surfactants For Smoother Films Nature Energy

Thin Film Coating Solution Processing Techniques Compared Ossila

Bilateral Alkylamine For Suppressing Charge Recombination And Improving Stability In Blade Coated Perovskite Solar Cells Science Advances

100mm Adjustable Film Coating Applicator Film Coater With Micrometer Wet Film Preparation Device 0 3500mm Width Film Casting Doctor Blade Amazon Com

Doctor Blade Pt Victory Blessings Indonesia

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Thin Film Coating Solution Processing Techniques Compared Ossila

Defect Tolerant Perovskite Solar Cells From Blade Coated Non Toxic Solvents Journal Of Materials Chemistry A Rsc Publishing

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A Rsc Publishing

Thin Film Processing Method Part 1

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Doctor Blade Materials And Profiles Pamarco

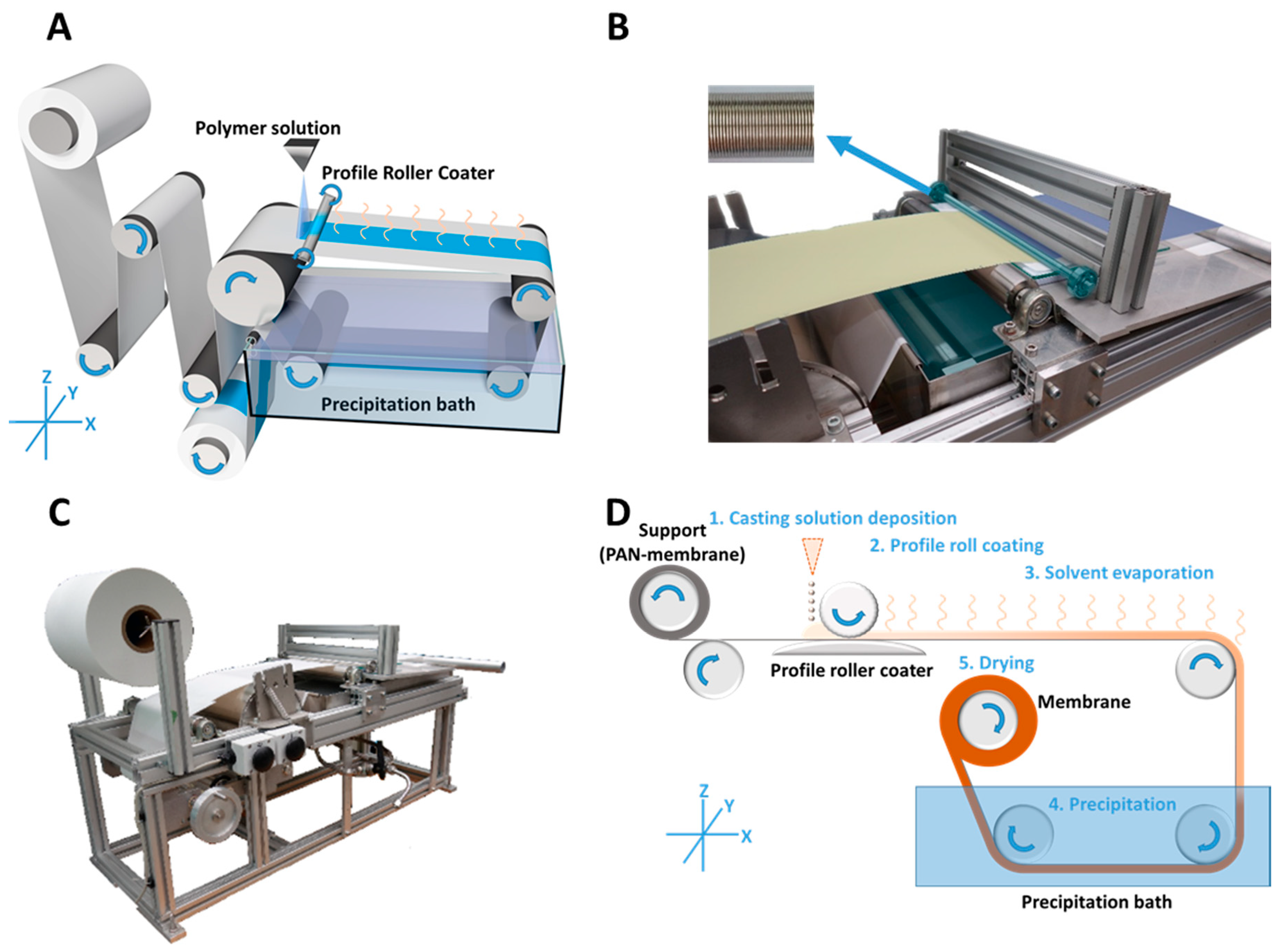

Membranes Free Full Text Formation Of Thin Isoporous Block Copolymer Membranes By An Upscalable Profile Roller Coating Process A Promising Way To Save Block Copolymer Html

An Overview Of Roll Coating New Era Converting

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Link Springer Com Content Pdf 10 1007 2f978 0 387 853 5 10 Pdf

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

A Blade Coating Study Using A Finite Element Simulation Physics Of Fluids Vol 17 No 12

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing

Sensitive Material Deposition Protocol According To A Doctor Blade Method Download Scientific Diagram

Improvement On The Performance Of Perovskite Solar Cells By Doctor Blade Coating Under Ambient Condition With Hole Transporting Material Optimization Sciencedirect

Knife Coating An Overview Sciencedirect Topics

Arxiv Org Pdf 1811

Www Ecolab Com Media Widen Nalco Water Pulp Paper R 902 Chatter And Soft Tissue Production Process Driven Mechanisms Pdf Pdf

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

Doctor Blade Method Explained Youtube

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A Rsc Publishing

Automatic Film Coater Doctor Blade Youtube

Why Is A Doctor Blade Important Youtube

Doctor Blade Technique Download Scientific Diagram

Large Scale Deposition Of Organic Solar Cells Ossila

A Schematic Diagram Of Doctor Blade Technique B Fe Sem Download Scientific Diagram

Gravure Coating Method For Protective Film Labels Coating Gs Coater