Doctor Blade Method

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

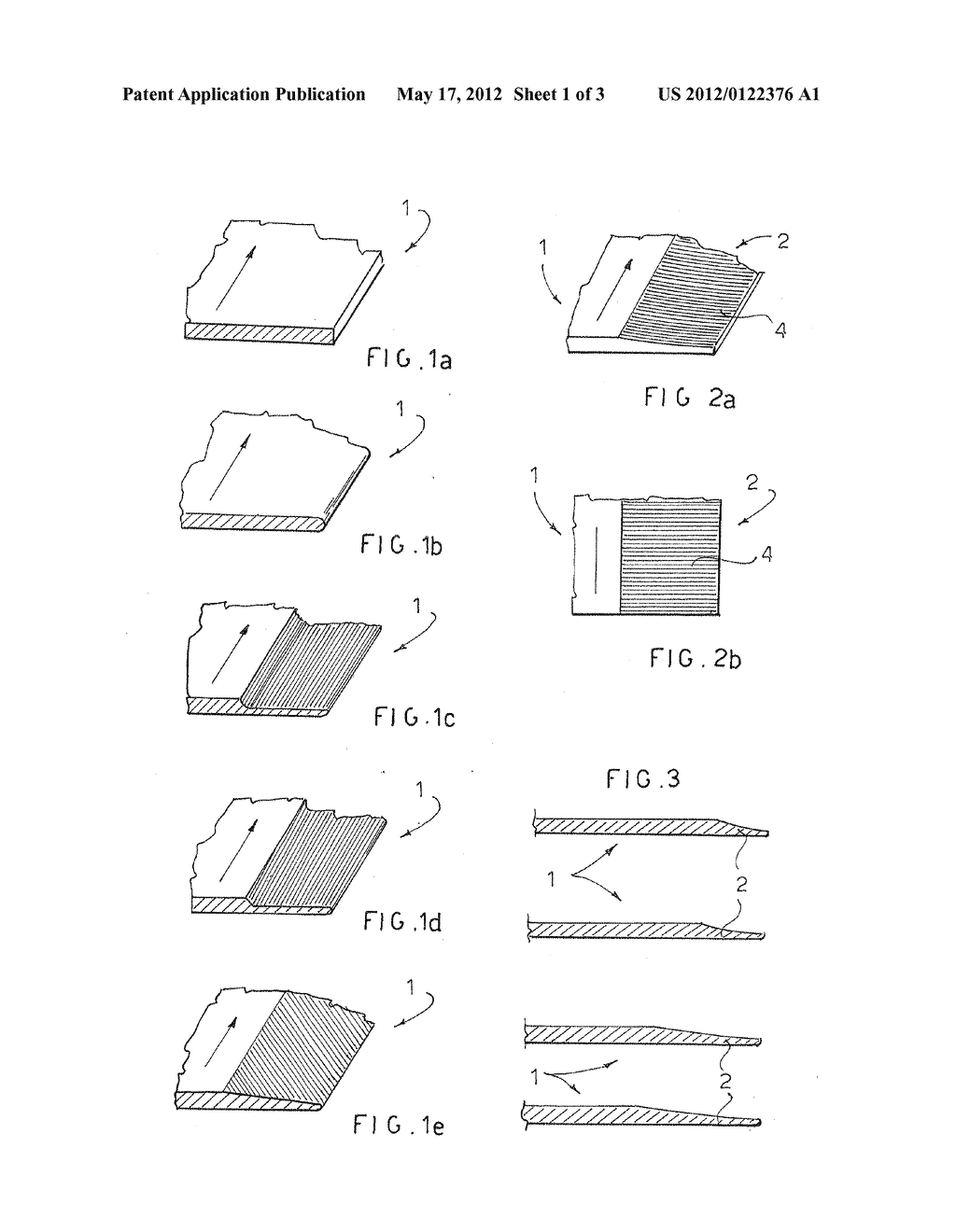

Pre Honed Doctor Blade With A Curved Profile Lamella And Method For Producing Said Doctor Blade Diagram Schematic And Image 02

Improvement On The Performance Of Perovskite Solar Cells By Doctor Blade Coating Under Ambient Condition With Hole Transporting Material Optimization Sciencedirect

Doctor Blade Archives Flexoglobal Blog

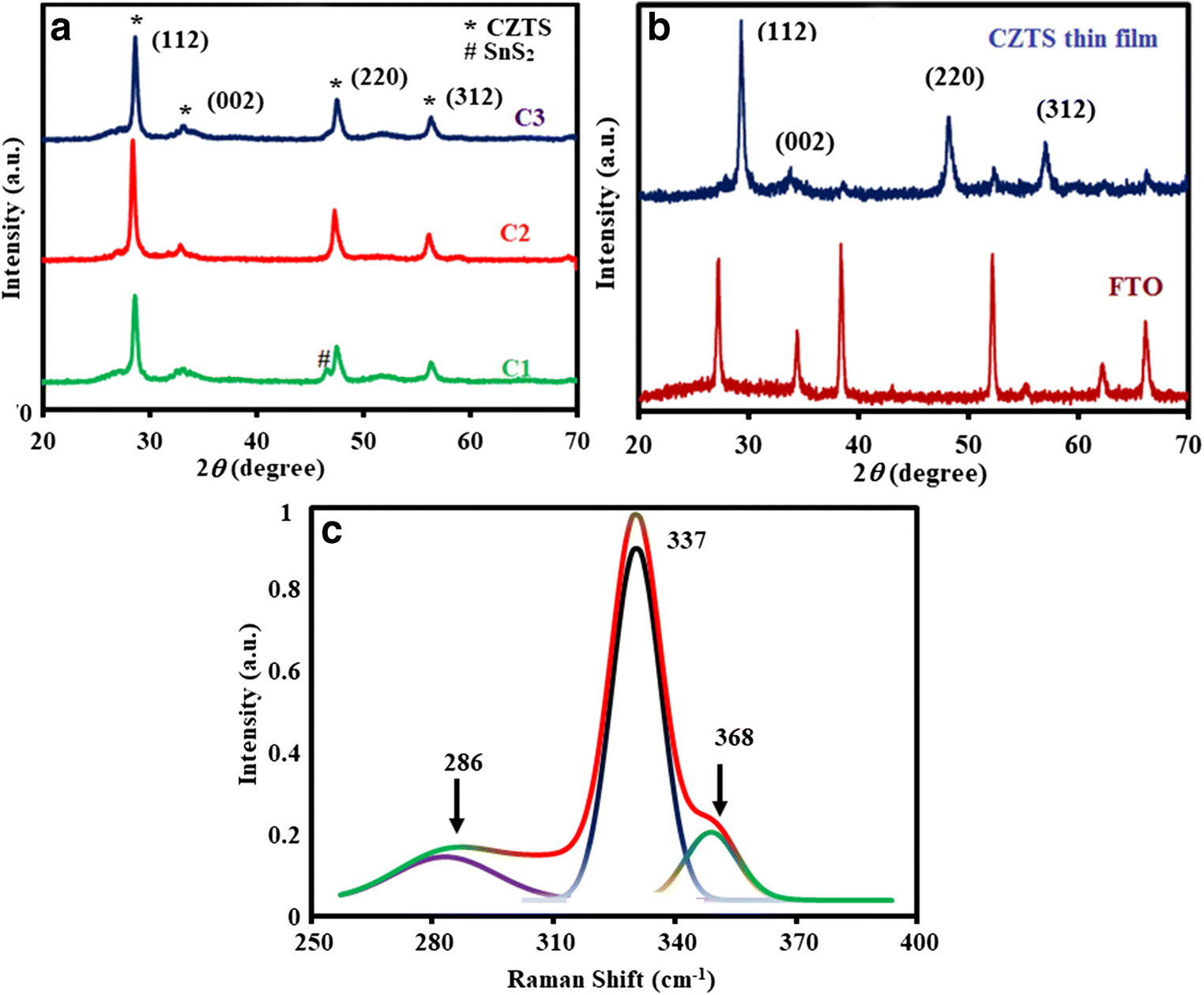

A Schematic Of The Doctor Blade Setup Reprinted With Permission From Download Scientific Diagram

Link Springer Com Content Pdf 10 1007 2f978 0 387 853 5 10 Pdf

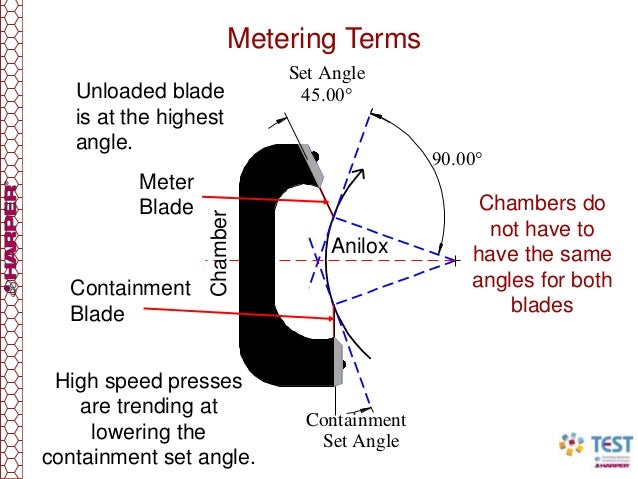

Switching to thin, wider blades Usually done on the containment side of the chamber, press crews will employ this method as a quick fix As the press continues to run, however, this actually allows for unwanted ink debris to more easily pass under the extended, wider blade—causing a number of more severe and unwanted issues.

Doctor blade method. A method of lessening or preventing coverage comprising the steps of placing a doctor blade in contact with a surface of a rotating cylinder, reciprocating the doctor blade generally transverse to the direction of cylinder rotation, and automatically and repetitiously increasing and decreasing doctor bladecylinder contact pressure in response. HD DOCTOR BLADE Like all flexo process components, the doctor blade has evolved to the point that many blade materials, commonly used in 1980, are no longer available To understand the driving forces in this evolution, it’s important to first review the fundamental function of a doctor blade. The method of claim 1 wherein said doctor blade is comprised of spring steel 4 The method of claim 1 wherein the width of said doctor blade is at least as wide as the width of said work surface Description BACKGROUND OF THE INVENTION The invention relates to the art of pad transfer printing, and more particularly to an improved doctor.

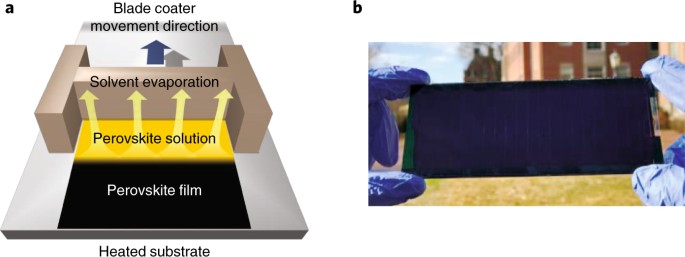

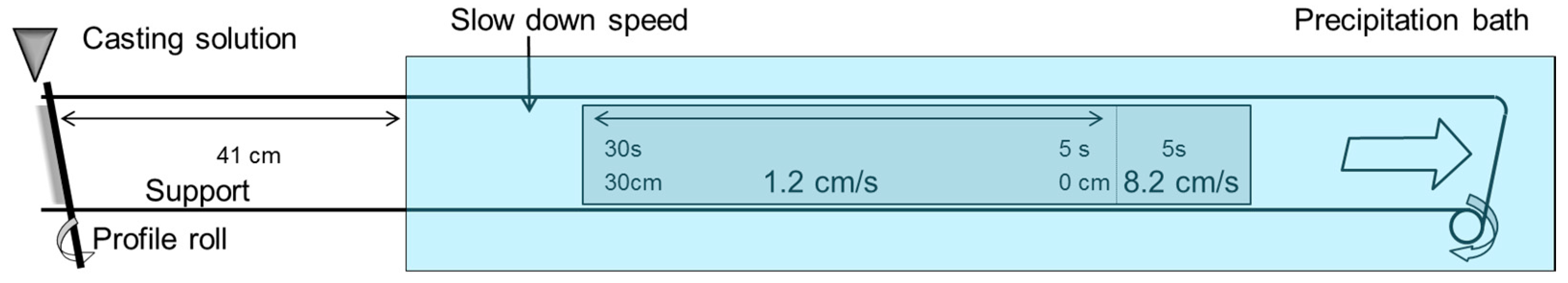

Photographs of the hierarchical nanoporous membranes created using a doctor blade coating method A, Photograph of largearea HNM (10 × 10 cm2 ) fabricated by a doctorblade method. By solgel method with doctor blade technique for dye sensitized solar cell Was prepared by doctor blade technique The TiO 2 powder 7990 % was mixed into 01 M nitric acid (HNO 3) solution adding DI water until pH 3 – 4 completely and added Triton X100 for surfactant Based on was coated on TCO glass by doctor blade technique. Interestingly, the carrier diffusion length in doctorbladed OTP films is beyond 35 μm which is significantly larger than in the spincoated films, due to the formation of crystalline grains with a very large size by the doctorblade coating method.

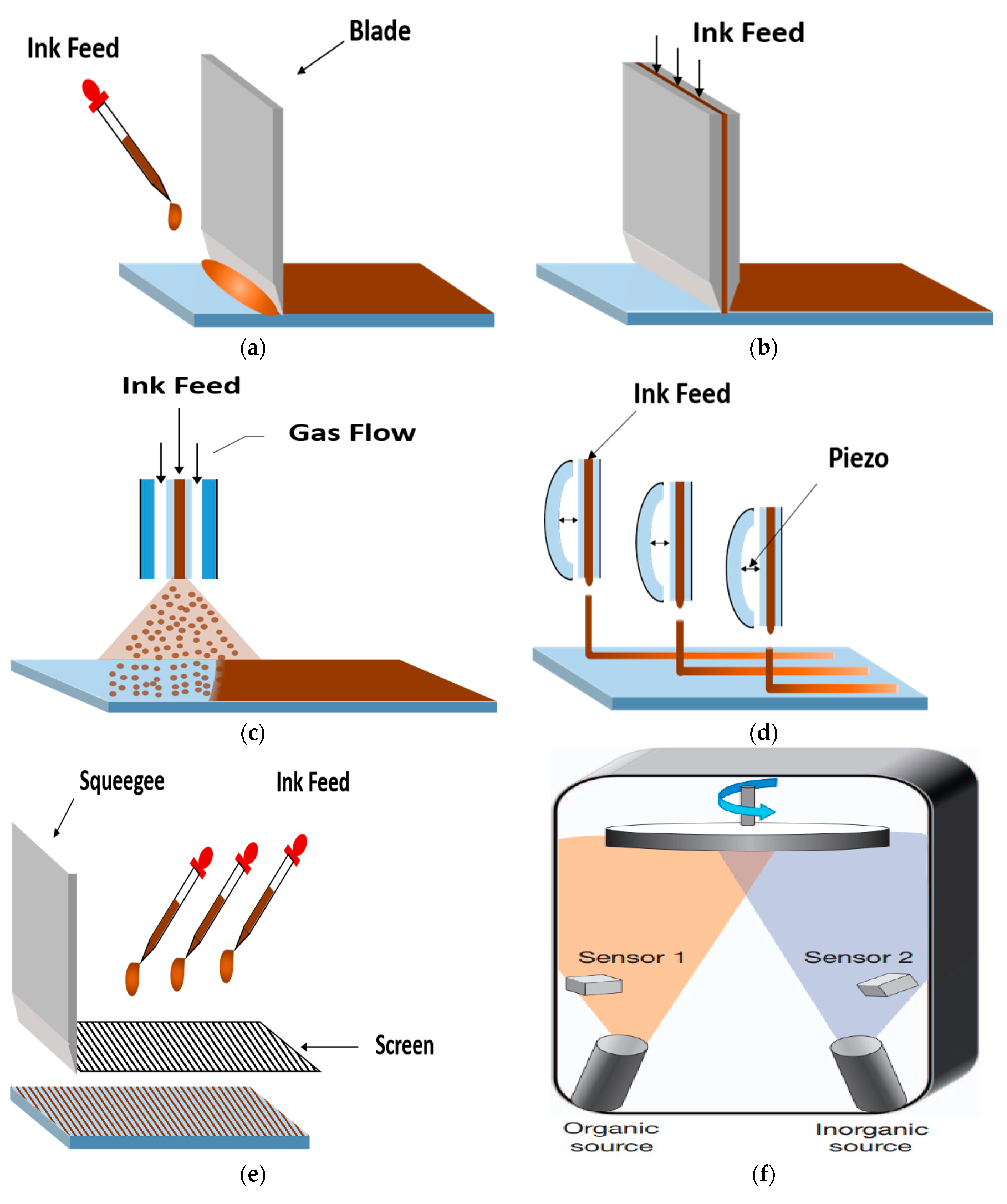

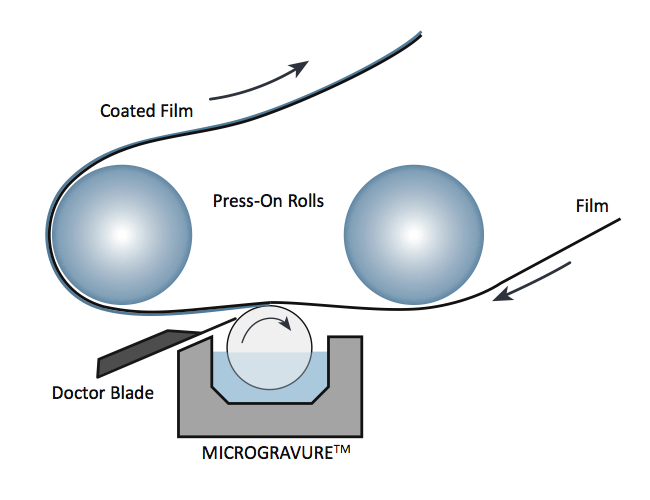

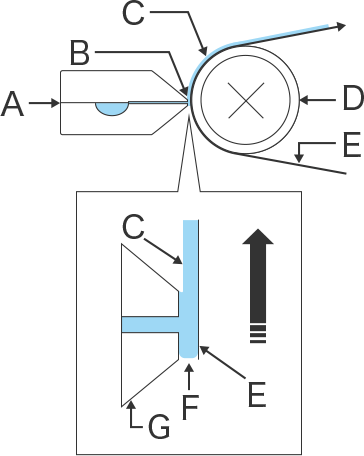

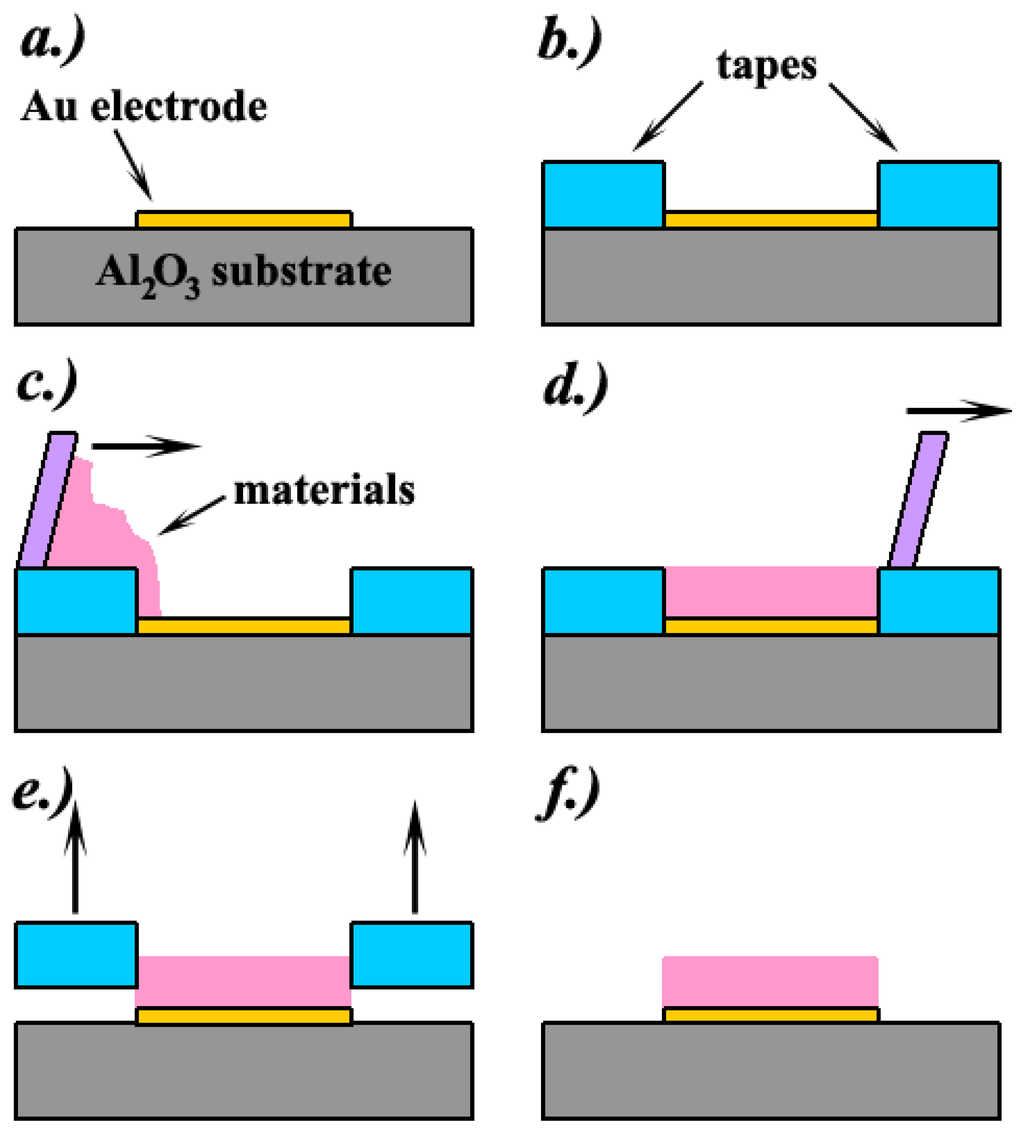

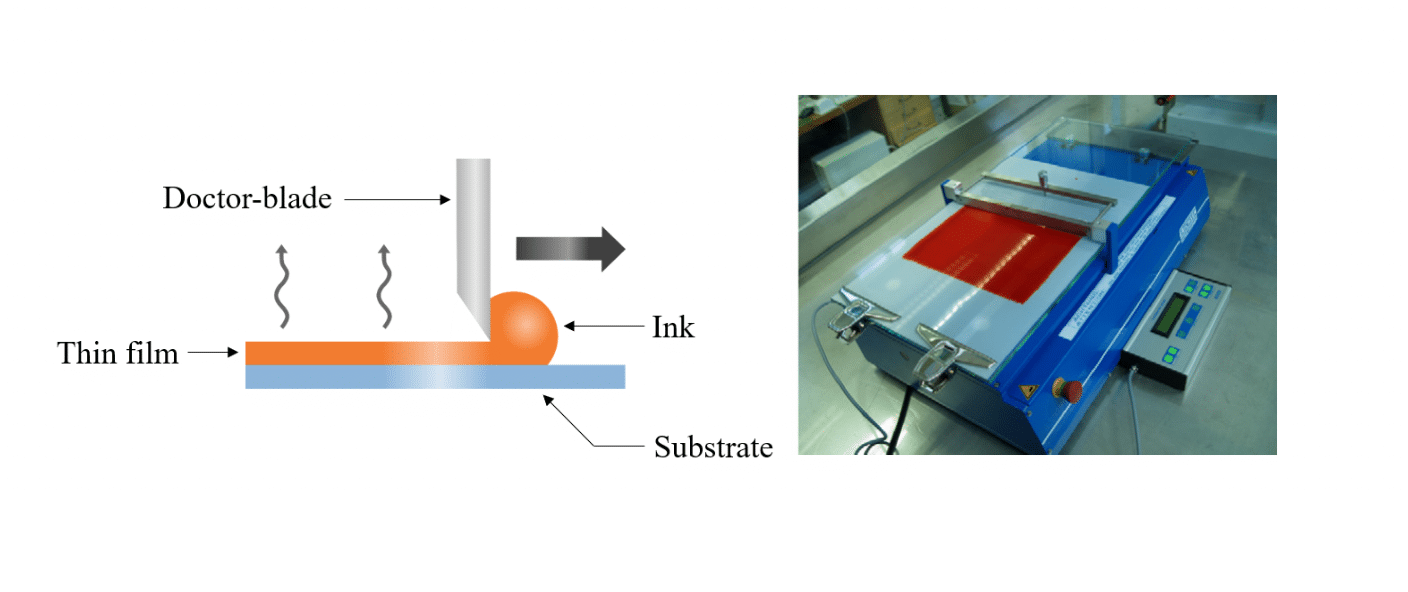

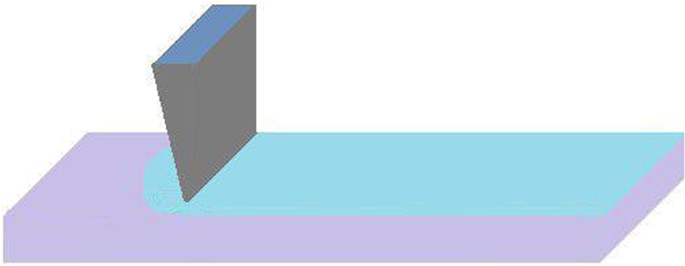

Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. Doctor Blading Doctor blading also known as knife coating or blade coating is a popular thinfilm fabrication technique It involves either running a blade over the substrate or moving a substrate underneath the blade There is a small gap that determines how much solution can get through Here, solution is effectively spread over the. Doctors blade method is used for making thin layers, and I think it is not possible to make thin films with this technique, because thin films are normally deposited by chemical or physical vapor.

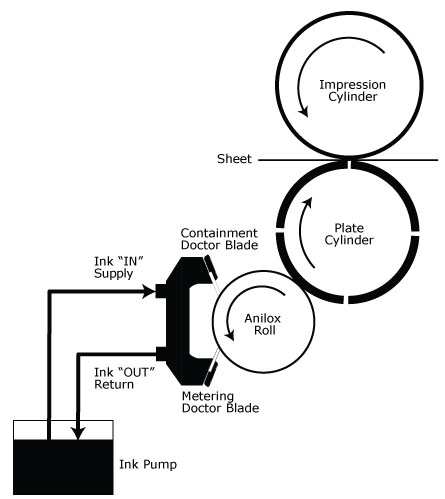

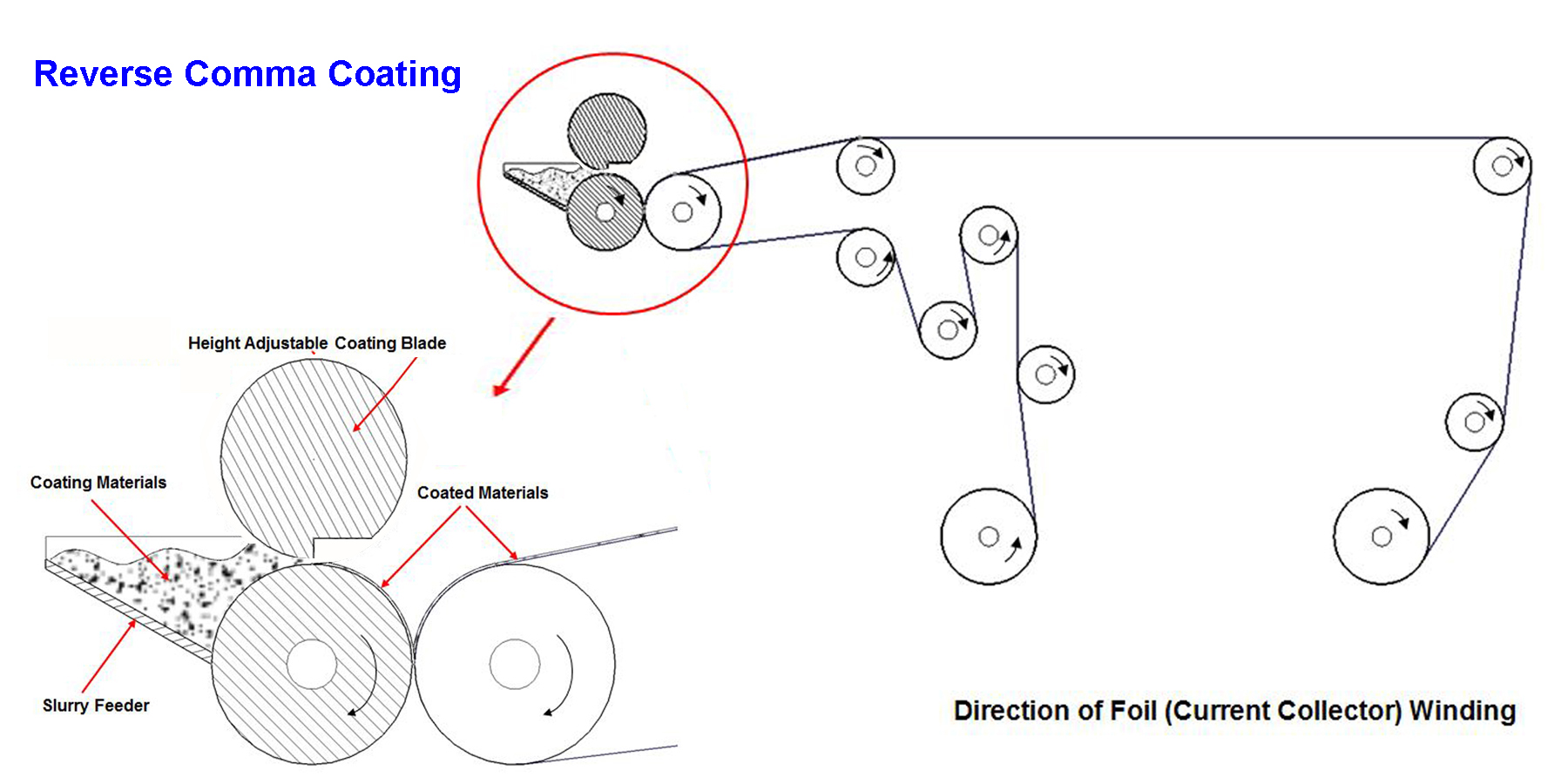

Doctor Blades are actually an essential part of commercial printing While there are many methods of printing, there are two predominant methods that use Doctor Blades They are called Rotogravure (gravure), and Flexographic (flexo) printing In both Gravure and Flexo printing, the doctor blade is technically a metering blade. The doctor blade chamber system offers the latest "toolless" feature for fast blade and end seal changes reducing down time Monoblade chambers designs are also available RetroFit to existing machines options with a full design and engineering service System Operation. The method of doctor blade installation is important Improper installation will influence the ink removal effects and the lifespan of the doctor blade and cylinder We can provide coating doctor blades, coating dotor blades, and carbon steel blades Different doctor blades offer different suitable printing speeds.

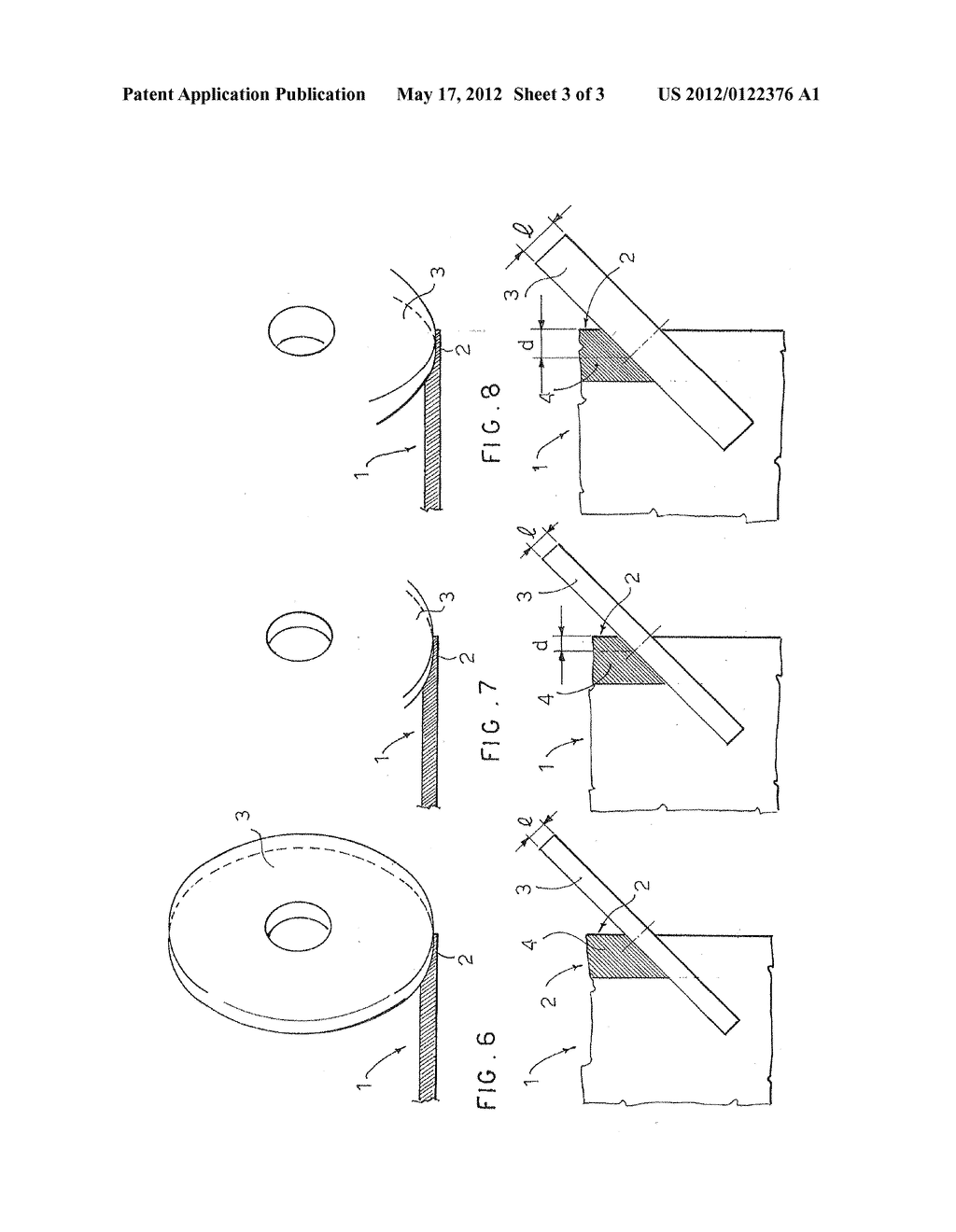

Doctor blade The operation of filling with conductive paste using the doctor blade is similar to the same operation with a squeegee in the screen printing method Therefore, we selected a conductive paste that contained ethyl cellulose as binder, because the ethyl cellulose has been used in the screen printing method and also shows high thixo. Doctor blades are traditionally designed in 3 main tip configurations straight, bevel and lamella A straight doctor blade has a straight, blunt edge and is used for lower quality print A beveled doctor blade is cut at an angle creating a beveled edge. A method for the manufacture of the doctor blade of a fiber web machine, where the fiber material used in the composite structure of the doctor blade is impregnated by means of a matrix material and after this the composite structure is hardened, wherein the fiber material is essentially free from carbon fiber and that particulate carbon is.

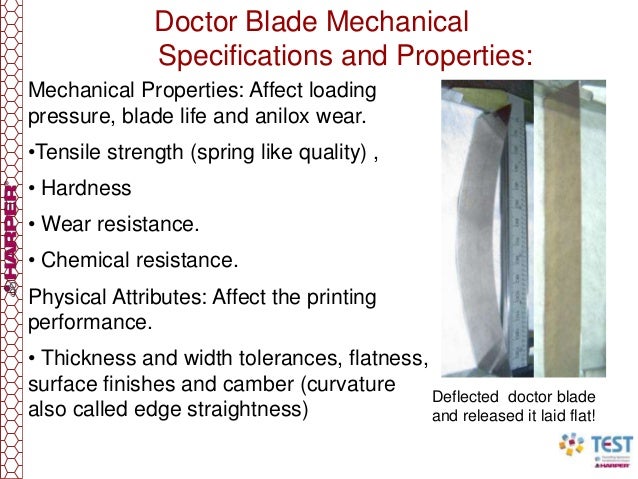

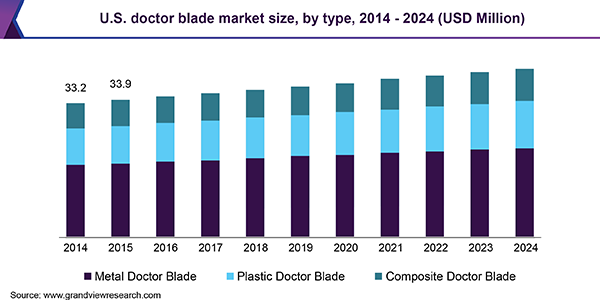

Custom Engineered Doctor Blade Holders To be highly successful in business, you need the proper tools to ensure superior quality and productivity Gravure and flexographic printing methods demand high precision equipment from prepress to postpress Having the right tools to produce quality products and to reduce press downtime is crucial. The doctor blade is mounted in a way that it uniformly meters the ink from the anilox prior to distribution onto the printing plate, as shown in the illustration Key factors of success include Angle of blade to anilox roll per press specs Correct pressure of blade needed to roll (the least amount needed) Perfect alignment with the anilox axis. Offset is the traditional and economical printing method, commonly used for newspapers, books, magazines, brochures, and pamphlet printing The doctor blade is a thin piece of metal, plastic, rubber, or composite material Plastic blades are expected to witness the fastest growth in terms of demand in the forthcoming years.

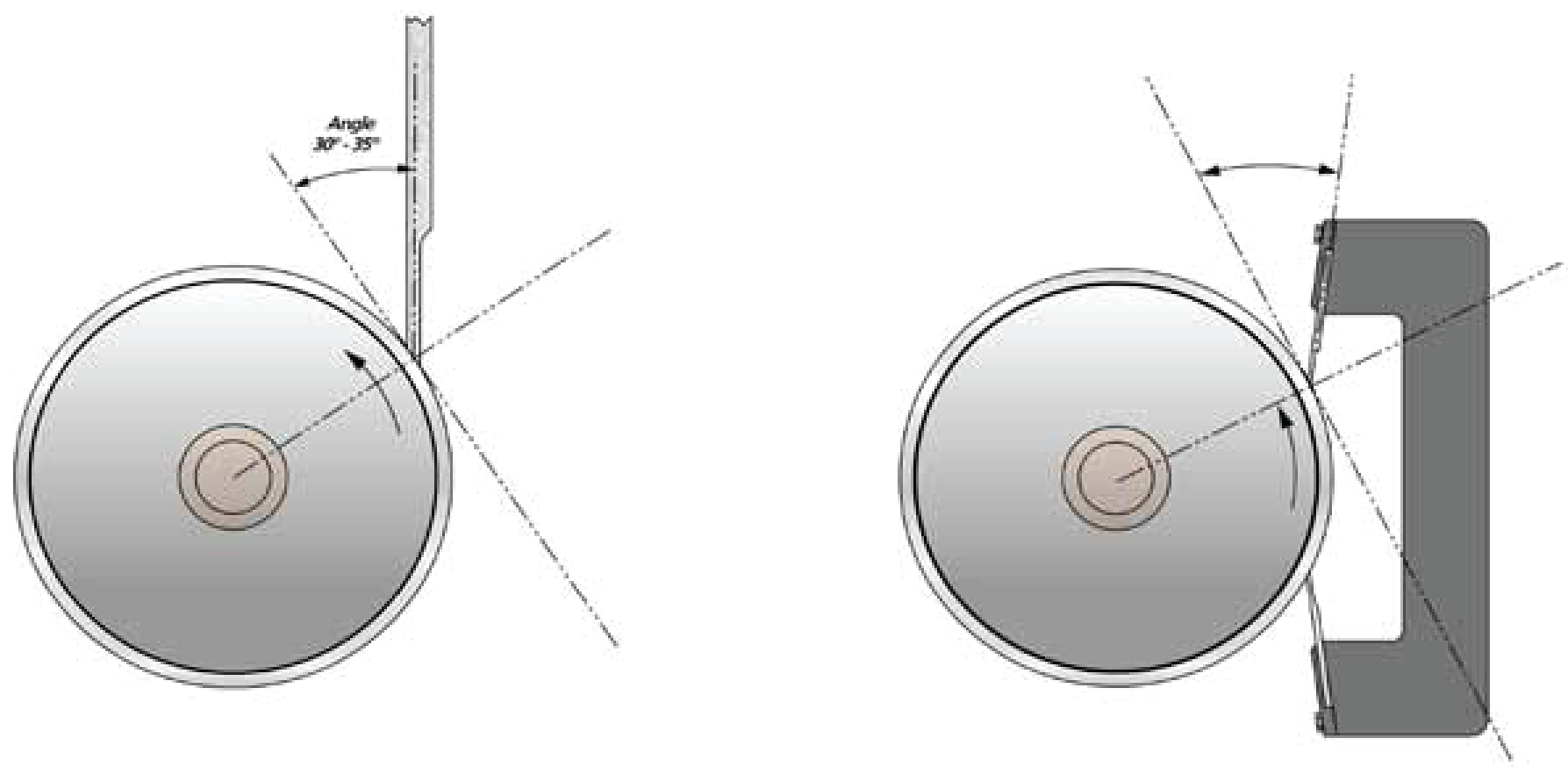

Doctor blade method c Calendering d chillroll extrusion e transfer molding f spinning g blown film extrusion process c calendering d chillroll extrusion g blownfilm extrusion process. The welldefined thickness of films fabricated using the doctor blade technique is detailed in Figure 3 This method, aptly named tape casting, knife coating, or knifeoveredge coating, due to transfer to reelto reel coating (R2R), is also viable to be used to make films for polymer solar cells The stages of this technique are summarized as. In reverse angle and chamber blade applications, the doctor blade angle should be between 28° and 32° If the blade angle drops below 28°, a larger part of the blade’s edge will come into contact with the roll.

Method Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and "ductor" became doctor A technician installs a doctor blade for flexographic. Blade loading There are four basic methods of loading a doctor, they are 1 Mechanical spring 2 Pneumatic/Hydraulic cylinder 3 Gravity 4 Holder loaded (hose loaded doctor blade holder), doctor locked by turnbuckles NOTE The crosssection of any doctor beam is very small in comparison to its length The result of this is. He also says that since every print shop is different, a method should be determined for replacing blades, and whether it's daily or weekly, it should be consistent Stamey goes on to explain that if an anilox is changed "plus or minus more than 100 line screen," the doctor blade should always be replaced 3 Choose The Chamber Wisely.

Doctor blade method c Calendering d chillroll extrusion e transfer molding f spinning g blown film extrusion process c calendering d chillroll extrusion g blownfilm extrusion process. A method of lessening or preventing coverage comprising the steps of placing a doctor blade in contact with a surface of a rotating cylinder, reciprocating the doctor blade generally transverse to the direction of cylinder rotation, and automatically and repetitiously increasing and decreasing doctor bladecylinder contact pressure in response. Many translated example sentences containing "doctor blade method" – GermanEnglish dictionary and search engine for German translations.

Our Doctor Blades are available in all different edge types, standard thicknesses and widths They are supplied in 100 meter / 328 foot rolls in easytouse cassettes, or cut in lengths to meet your needs The preground blades have radiusground edges, enhancing blade functionality The blade and cylinders last longer than conventional blades. An object of the present invention is to prevent a doctor blade from being scraped by a filler contained in a coating liquid The surface of the doctor blade (1) for scraping off the coating liquid on the peripheral surface (6) of the coating roller (5) for applying a coating liquid containing a filler to a traveling separator is made of ultrahigh molecular weight polyethylene. For more information, visit our websitehttp//inbguacil/teva/chem/eng/mennysh/Pages/defaultaspxMusic CreditsIt's Near by Dj QuadsDj Quads on Soundcloud.

Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors and is now an accepted precision coat ing method. The term "doctor blade" is thought to originally come from the German term "ductor blade" Doctor blades can be made of either a plastic material or a metal such as steel The thickness of different types of doctor blades can vary greatly;. Additionally, the ability to use solution processing techniques with MXene dispersions, such as vacuum‐assisted filtration and doctor blade coating methods, can potentially make conductive MXene coatings that can eliminate the use of external metal current collectors, thus reducing the electrode cost and process complexity.

Methods for doctor blade measurement and setup are provided, as well as basic doctor blade troubleshooting information The appendix is a blade troubleshooting chart based on recognizing blade wear patterns (The scope of this paper does not include creping or coating blades Additionally, the paper uses as. Our Doctor Blades are available in all different edge types, standard thicknesses and widths They are supplied in 100 meter / 328 foot rolls in easytouse cassettes, or cut in lengths to meet your needs The preground blades have radiusground edges, enhancing blade functionality The blade and cylinders last longer than conventional blades. With these catalyst coating methods, doctor blade method is an efficient way for realizing a high precision in catalyst loading with high reproducibility Bender et al 12 coated the catalyst on a Teflon film by the doctor blade method and pointed out that this process is significantly more precise and faster than the hand painting process 12.

Our designed doctorblade method shows the advantages of highly versatile, uniform, and freestanding membranes with a precisely controlled thickness Figure 5B shows freestanding and flexible HNM HNMs show a greater degree of corrugation compared to pure GOs due either to the development of hierarchical pores or to defects on the sheets. Blade loading There are four basic methods of loading a doctor, they are 1 Mechanical spring 2 Pneumatic/Hydraulic cylinder 3 Gravity 4 Holder loaded (hose loaded doctor blade holder), doctor locked by turnbuckles NOTE The crosssection of any doctor beam is very small in comparison to its length The result of this is. The effect of cell We have demonstrated a modified doctorblade method size including 5x5 mm2, 5x10 rnrrr', 5x mm2 and using a dense Ti02 paste in combination with moderate 2 5x 100 mm on the efficiency of DSSC was also compression for preparation of Ti02 thin film.

By solgel method with doctor blade technique for dye sensitized solar cell Was prepared by doctor blade technique The TiO 2 powder 7990 % was mixed into 01 M nitric acid (HNO 3) solution adding DI water until pH 3 – 4 completely and added Triton X100 for surfactant Based on was coated on TCO glass by doctor blade technique. Doctor Blading Doctor blading also known as knife coating or blade coating is a popular thinfilm fabrication technique It involves either running a blade over the substrate or moving a substrate underneath the blade There is a small gap that determines how much solution can get through Here, solution is effectively spread over the. Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors and is now an accepted precision coating method.

Methods for doctor blade measurement and setup are provided, as well as basic doctor blade troubleshooting information The appendix is a blade troubleshooting chart based on recognizing blade wear patterns (The scope of this paper does not include creping or coating blades Additionally, the paper uses as. Within each toner cartridge is a series of components that work together to deliver you flawless prints This video showcases the doctor blade, and the impor. The blades need to have a long lifespan in order to reduce the change time of doctor blade and increase efficiency Considering the above requirements, we recommend the following doctor blades which have high precision, good durability, long lifespan and are suitable for gravure printing.

In printing the doctor blade (from ductor blade) removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used. In printing the doctor blade (from ductor blade) removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used. Solar cells using a doctor blade method Doctorblade deposition has been used prevalently for various thin films in other types of thin film solar cells16– The appeal for utilizing doctor blading is primarily due to scalability for rolltoroll production, simplicity,andcosteffectiveness17,18 Furthermore,doctorbladingalso.

Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. However, the usedblade inspection usage is slightly unobvious, but moderately common within the industry, so I think it's worthy of mentioning In brief, the function that I am trying to find another reference for is the use of a goniometer for inspection of _used_ doctor blades when removed from the machine. Abstract We have demonstrated a modified doctorblade method using a dense TiO 2 paste in combination with moderate compression for preparation of TiO 2 thin film Dyesensitized solar cell (DSSC) with the working area of 025 cm 2 using that novel TiO 2 thin film was observed to show its superior photovoltaic performance at AM 15 V OC of 077 V, J SC of 1 mA/cm 2, FF of 050 and ¿ of 7.

Blade loading There are four basic methods of loading a doctor, they are 1 Mechanical spring 2 Pneumatic/Hydraulic cylinder 3 Gravity 4 Holder loaded (hose loaded doctor blade holder), doctor locked by turnbuckles NOTE The crosssection of any doctor beam is very small in comparison to its length The result of this is. Too steep an angle can damage the roll surface and/or doctor blade itself, while too little an angle may result in inadequate cleaning of roll surface February 14 Determination of Doctor Angle 2 3 A Simple Approach The objective of this presentation is to show a simple, very simple tool to determine angle of doctor blade on any roll. HD DOCTOR BLADE Like all flexo process components, the doctor blade has evolved to the point that many blade materials, commonly used in 1980, are no longer available To understand the driving forces in this evolution, it’s important to first review the fundamental function of a doctor blade.

Doctors blade method is used for making thin layers, and I think it is not possible to make thin films with this technique, because thin films are normally deposited by chemical or physical vapor. Generally they are not over 1/16 inches (16 mm) thick A doctor blade helps to make a uniform print. Within each toner cartridge is a series of components that work together to deliver you flawless prints This video showcases the doctor blade, and the impor.

Method Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and "ductor" became doctor A technician installs a doctor blade for flexographic. The Doctor Blade holder assembly looks like the figure below Generally fitted with pneumatic movement The blade angle is changeable The blade Oscillation system is motor driven The Backup or the Impression Roller This is a Rubber roller Width of this roller has to be slightly lesser than the web width The Rubber should be of Hardness 6065. The developed biosensor was compared against a dye sensitized photodetector fabricated by the traditional “doctor blade” method Detection of gold nanoparticle aggregation was possible for concentrations as low as 10 nM for the “doctor blade” system, and 15 nM for the inkjet printed photodetector.

A set of opaque films were prepared with Degussa P25 ® or Hombikat UV100 ® TiO 2 powders by the doctor blade method on glass slides with different compositions of polyethylene glycol of kDa (PEG), and they were characterized by spectroscopy, microscopy and photochemical kinetics measurements After annealing treatment at 450 °C, about 5–7% C atom was incorporated into the films, as a. Our designed doctorblade method shows the advantages of highly versatile, uniform, and freestanding membranes with a precisely controlled thickness Figure 5B shows freestanding and flexible HNM HNMs show a greater degree of corrugation compared to pure GOs due either to the development of hierarchical pores or to defects on the sheets. The doctor blade is mounted in a way that it uniformly meters the ink from the anilox prior to distribution onto the printing plate, as shown in the illustration Key factors of success include Angle of blade to anilox roll per press specs Correct pressure of blade needed to roll (the least amount needed).

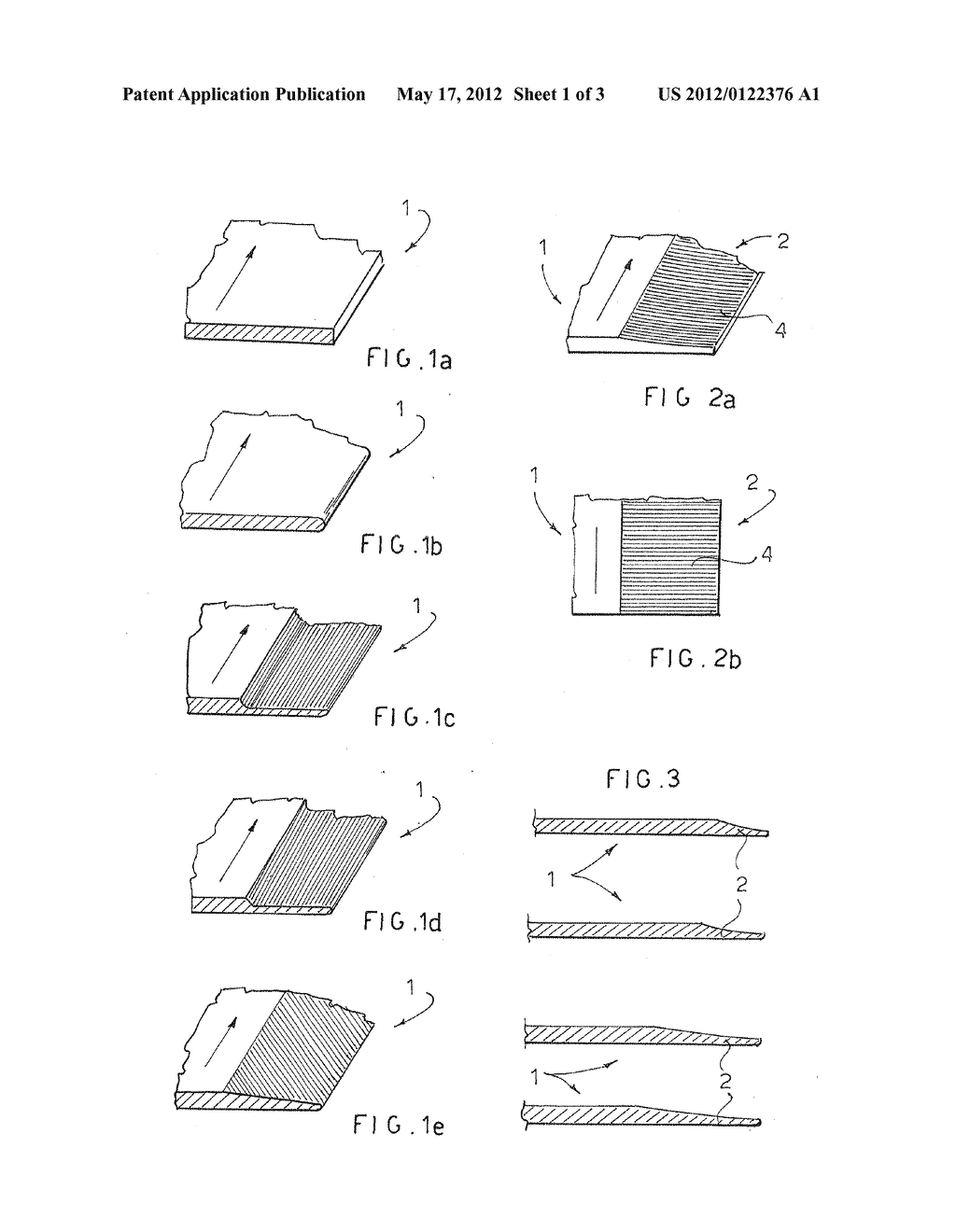

Figure 10 Czts Counter Electrode In Dye Sensitized Solar Cell Enhancement In Photo Conversion Efficiency With Morphology Of Tio 2 Nanostructured Thin Films Springerlink

Composite Doctor Blade And Method Of Its Production

Fabrication Schema Of The Doctor Blade Method Download Scientific Diagram

New Materials For Thin Film Solar Cells Intechopen

Doctor Blade Coated With Polymeric Material And Coating Method Patent

Pubs Acs Org Doi Pdf 10 1021 Lav

Doctor Blade Method Explained Youtube

Doctor Blade Archives Flexoglobal Blog

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Preparation And Transport Properties Of Oriented Buckypapers With Single Walled Carbon Nanotubes

The Gravure Printing Process Allison Systems

Doctor Blade Method For Coating 10 Download Scientific Diagram

New Polymers Meter Like Steel Doctor Blades Flexoglobal Blog

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

Www Osapublishing Org Viewmedia Cfm Uri Jlt 30 21 3316 Seq 0

Fabrication Schema Of The Doctor Blade Method Download Scientific Diagram

Knife Coating An Overview Sciencedirect Topics

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

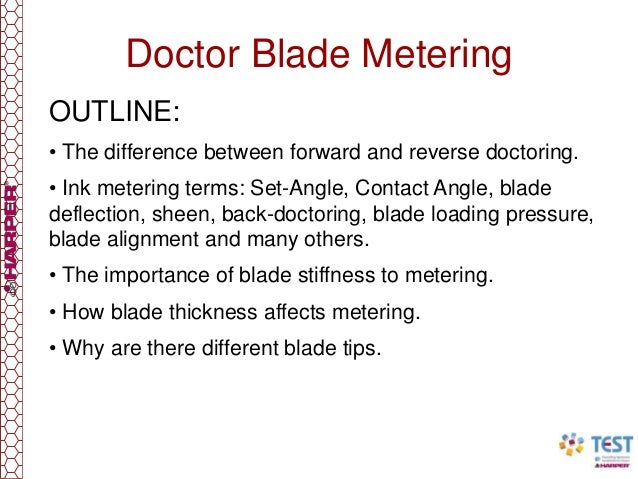

Doctor Blade Metering

Digital Flexo Photopolymer Plate Flexographic Printing Printing Method

Automatic Film Coater Doctor Blade Youtube

Tsapps Nist Gov Publication Get Pdf Cfm Pub Id

Doctor Blade Pt Victory Blessings Indonesia

Why Is A Doctor Blade Important Youtube

Hybrid Film Applicator Doctor Blade 150mm Slot Die 100mm Heads Eq Hds 150 Youtube

Metals Free Full Text Major Impediment To Highly Efficient Stable And Low Cost Perovskite Solar Cells Html

Q Tbn And9gcs5fhxjbbqdytiv5bt0vwpc4j9vmyr2cjxaufx9d6s6n0meqshz Usqp Cau

Doctor Blade Metering

Www Spiedigitallibrary Org Proceedings Download Fulldoi 10 1117 2f12

Screen Printing Screen Printing Basics The Theory Of Screen Printing Screen Printing Types Printing Flat Circular Seal Mesh For Screen Printing Screen Printing Inks Screen Printing Is Like Silkscreen Print

Hd Flexo Blades Manualzz

Yasui Seiki In Us Roll To Roll Precision Custom Coating Machines

Photocatalytic Efficiency Tuning By The Surface Roughness Of Tio2 Coatings On Glass Prepared By The Doctor Blade Method1 Photochemistry And Photobiology X Mol

Roll Coating Coating Dispensing Methods Coating Dispensing Technology Keyence America

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

Flexo Print Guide By Gulzar Hussain Issuu

Sensors Free Full Text Improvement Of Flame Made Zno Nanoparticulate Thick Film Morphology For Ethanol Sensing Html

Aip Scitation Org Doi Pdf 10 1063 1

Doctor Blading Materials Processing Britannica

Schematic Representations Of A The Doctor Blade Method And B The Download Scientific Diagram

Thin Film Coating Solution Processing Techniques Compared Ossila

Scholarworks Wmich Edu Cgi Viewcontent Cgi Article 1269 Context Hilltopreview

American Label Group Inc

Doctor Blade Technique Download Scientific Diagram

Surfactants For Smoother Films Nature Energy

Www Osti Gov Servlets Purl

Knife Coating An Overview Sciencedirect Topics

Doctor Blade Technique And Three Electrode Setup Download Scientific Diagram

Q Tbn And9gcqltyimhbqreqo7nffmzyv6q9xmazyk28lvmo0jjrmyvja1xrag Usqp Cau

Print Method Gravure Melvin Magro

The Role Of Physical Techniques On The Preparation Of Photoanodes For Dye Sensitized Solar Cells

Arxiv Org Pdf 1811

Fabrication Of Nanostructured Nio Thick Films By Facile Printing Method And Their Dye Sensitized Solar Cell Performance Scientific Net

Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Semantic Scholar

Onlinelibrary Wiley Com Doi Pdf 10 1002 Aenm

Corrugated Ink Delivery Systems Two Roll Or Doctor Blade

A Schematic Diagram Of Doctor Blade Technique B Fe Sem Download Scientific Diagram

Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Semantic Scholar

Pdf Fabrication Of Dye Sensitized Solar Cell Using Spray Coating Method Agus Purwanto Academia Edu

Doctor Blade Selection Guide Dekejie Com

Www Allisonblades Com Wp Content Uploads Sites 4850 17 05 Flexo June12 Pdf

Pdf Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Tan Hoang Academia Edu

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing

Gallus Ferd Ruesch Ag Printing Machines And Solutions For The Label Printing And Folding Carton Printing Key Factors Influencing Flexographic Printing Part 1 Of 2

Thin Film Processing Method Part 1

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

Flexography Wikipedia

Link Springer Com Content Pdf 10 1007 2f978 0 387 853 5 10 Pdf

Schematic Representation Doctor Blade Technique And Photograph Of Download Scientific Diagram

Thin Film Coating Solution Processing Techniques Compared Ossila

Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Semantic Scholar

Global Doctor Blade Market Size Share Industry Report 19 24

Usb2 Apparatus For Measuring The Wear Of A Doctor Blade And Method In Measuring The Wear Of A Doctor Blade And In Controlling A Paper Machine Google Patents

Doctor Blade Metering

Sensitive Material Deposition Protocol According To A Doctor Blade Method Download Scientific Diagram

Epa1 Pre Honed Doctor Blade With A Curved Profile Lamella And Method For Producing Said Doctor Blade Google Patents

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A X Mol

Membranes Free Full Text Formation Of Thin Isoporous Block Copolymer Membranes By An Upscalable Profile Roller Coating Process A Promising Way To Save Block Copolymer Html

Doctor Blade Coated With Polymeric Material And Coating Method Patent

Transparent Display Using A Quasi Array Of Si Sio 2 Core Shell Nanoparticles Scientific Reports

Doctor Blade Deposition Of Quantum Dots Onto Standard Window Glass For Low Loss Large Area Luminescent Solar Concentrators Nature Energy

The Role Of Physical Techniques On The Preparation Of Photoanodes For Dye Sensitized Solar Cells

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Usb2 Apparatus For Measuring The Wear Of A Doctor Blade And Method In Measuring The Wear Of A Doctor Blade And In Controlling A Paper Machine Google Patents

Photovoltaic Performance Of A N719 Dye Based Dye Sensitized Solar Cell With Transparent Macroporous Anti Ultraviolet Photonic Crystal Coatings Rsc Advances Rsc Publishing

Q Tbn And9gcqmpoxs3rwcdvl5qsahuszvdjoycqbp4s7hz W3 G0 Usqp Cau

Doctor Blade Pt Victory Blessings Indonesia

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Tape Casting An Overview Sciencedirect Topics

Hd Flexo Doctor Blades High Demand High Definition Flxon

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Figure 2 From Photocatalytic Degradation Of An Azo Textile Dye C I Reactive Red 195 3bf In Aqueous Solution Over Copper Cobaltite Nanocomposite Coated On Glass By Doctor Blade Method Semantic Scholar

Thin Film Coating Solution Processing Techniques Compared Ossila

Q Tbn And9gctybrkufeb59tshzjg6vmsi W0ivkoeery1wkg Vb Lclvdzs W Usqp Cau

The Role Of Physical Techniques On The Preparation Of Photoanodes For Dye Sensitized Solar Cells

Gravure Coating Method For Protective Film Labels Coating Gs Coater

Pre Honed Doctor Blade With A Curved Profile Lamella And Method For Producing Said Doctor Blade Diagram Schematic And Image 04